Where the Desert Meets Innovation

"In the Sonoran Desert, makers transform harsh landscapes into products of beauty and utility."

Innovation in the Desert

Arizona's manufacturing tradition is written in the landscape itself. From the copper mines of Bisbee to the aerospace facilities of Tucson, from the ranchlands of the east to the Indian reservations of the north, Arizona's makers have learned to work with the land's extremes. The brands featured here represent the diversity of Arizona's manufacturing: handcrafted dinnerware from premium materials, leather goods that honor the cowboy tradition, desert botanicals transformed into gourmet foods, innovations in beauty and nail care, architectural wind bells, and professional-grade sports equipment. Each product carries the spirit of Arizona: bold, beautiful, and built to last.

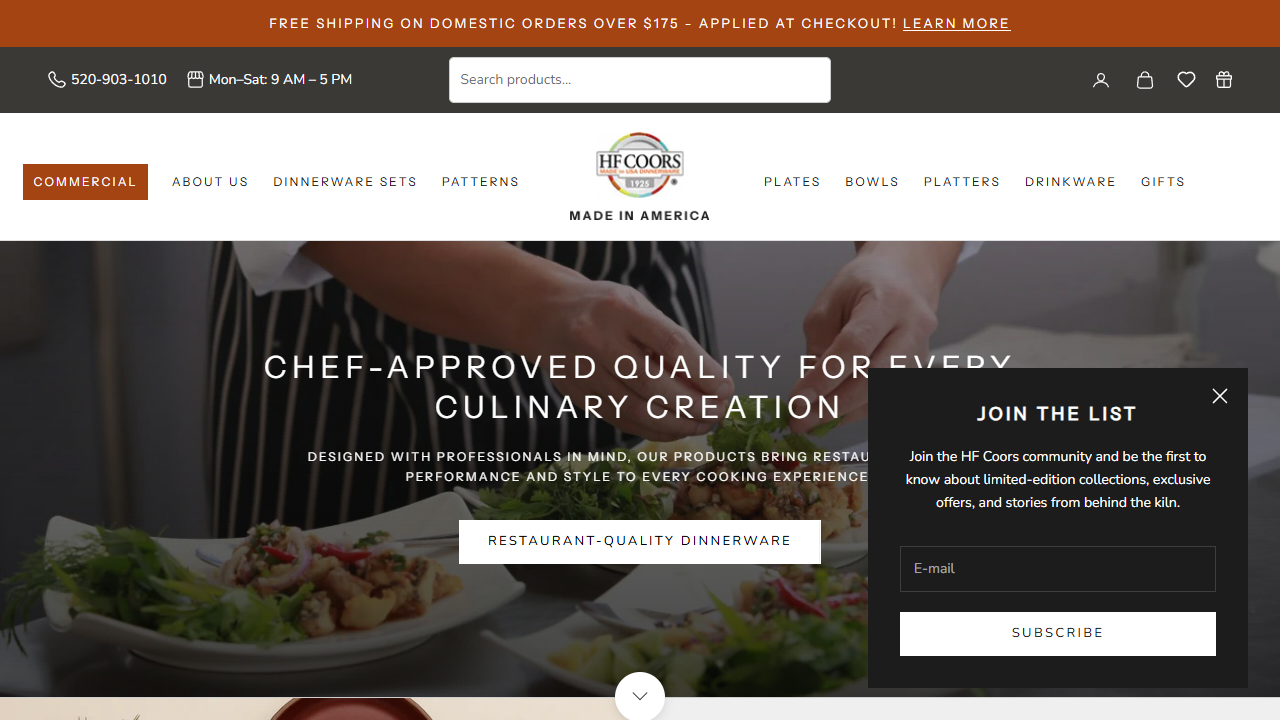

HF Coors

"Premium handcrafted ceramic dinnerware for restaurants and homes."

A Family Legacy

HF Coors represents the intersection of art and utility in Arizona's manufacturing landscape.

The company produces premium ceramic dinnerware that has become the standard for restaurants and discerning home cooks across America.

What sets HF Coors apart is their commitment to creating dinnerware that is both beautiful and functional, capable of withstanding the rigors of commercial kitchen use while maintaining an elegant appearance.

The company has built a reputation for quality that spans decades, with many of their pieces lasting for generations in both restaurant and home settings.

HF Coors understands that dining is an experience, and their dinnerware plays a crucial role in that experience, enhancing the presentation of food and creating a sense of occasion with every meal.

Time-Honored Techniques

The dinnerware manufacturing process at HF Coors begins with carefully selecting premium ceramic materials that meet their exacting standards for durability and aesthetic appeal.

Each piece is formed using traditional ceramic techniques combined with modern quality control methods.

The shaping process involves skilled artisans who understand the nuances of working with ceramic materials, ensuring that each piece has the perfect balance of form and function.

After forming, pieces undergo a rigorous firing process that transforms the raw ceramic into durable dinnerware capable of withstanding daily use in demanding environments.

The glazing process is where HF Coors truly shines, with glazes that are formulated to resist chipping, scratching, and staining while maintaining their beauty over time.

Each piece is inspected multiple times throughout the process to ensure it meets the company's high standards for quality and craftsmanship.

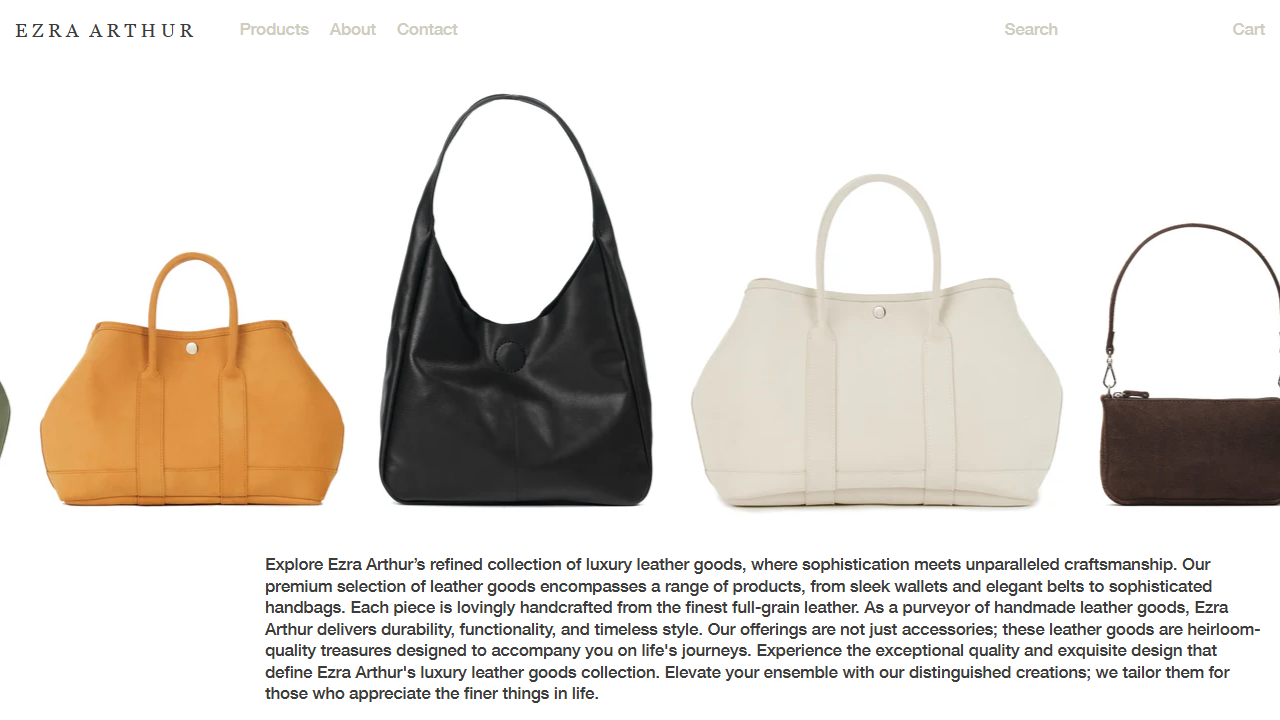

Ezra Arthur

"Handcrafted full-grain leather wallets, belts, and specialty notebooks."

A Living Tradition

Ezra Arthur, based in Phoenix, Arizona, defines itself as a maker of 'artifacts worthy of discovery,' a philosophy that rejects the disposable nature of modern fast fashion in favor of heirloom-quality goods designed to last a lifetime.

Owned and operated by four brothers, the company creates leather accessories that honor the spirit of the American West through rigorous craftsmanship and material purity.

The brand's foundational principle is the exclusive use of 100% full-grain leather, the highest grade available, which retains the hide's natural imperfections, strength, and ability to develop a rich, personalized patina over time.

The manufacturing process at Ezra Arthur is a deliberate blend of modern precision and traditional method, utilizing century-old equipment in their Phoenix workshop.

Time-Honored Techniques

Unlike many mass-market manufacturers that rely on 'genuine' leather (often bonded scraps) and synthetic shortcuts, Ezra Arthur products contain zero plastic, rubber, glue, or fabric linings—materials that typically degrade and cause a product to fail.

Instead, their wallets, belts, and cases are constructed solely of leather and high-grade metal hardware, assembled using traditional stitching and riveting techniques that ensure structural integrity.

For example, their belts are cut from thick, durable steer hide and finished with solid brass or nickel buckles, designed to hold up for decades of daily wear.

One of their standout products is the 'Small Leather Notebook,' a refillable journal that appeals to writers and professionals who value tactile quality.

The notebook features high-quality, acid-free paper bound in a rugged leather cover that protects the contents and ages beautifully.

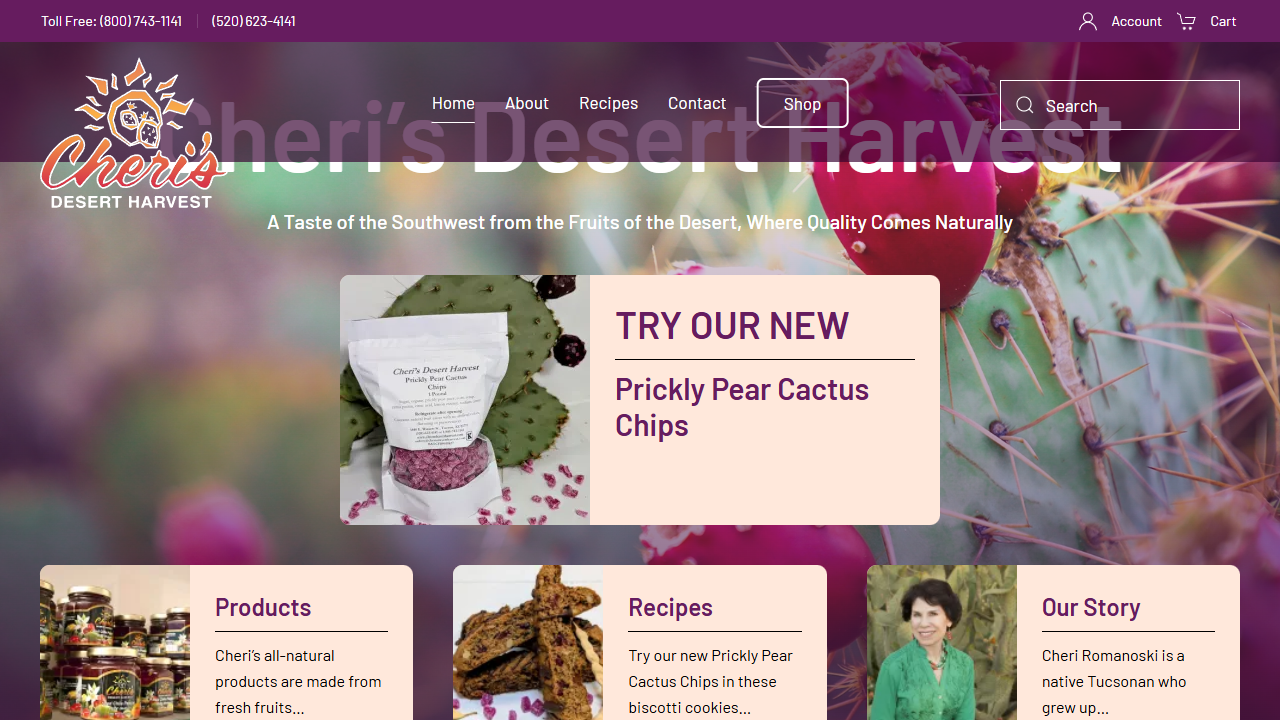

Cheri's Desert Harvest

"Prickly pear cactus jelly, syrups, and vegetable preserves."

Innovation Born from Necessity

Cheri's Desert Harvest is a quintessential Arizona brand that captures the unique flavors of the Sonoran Desert in a bottle.

Founded in 1985 by Cheri Romanoski, a Tucson native and former elementary school teacher, the company began as an educational hobby.

Romanoski wanted to teach her students and children about the indigenous flora of the desert and how Native Americans utilized these plants for survival.

This passion evolved into a commercial enterprise dedicated to preserving the authentic taste of the Southwest without artificial flavorings, colorings, or preservatives.

The core of the brand's operation is the prickly pear cactus fruit, known locally as 'tuna.'.

The Art of Handcrafted Excellence

The manufacturing process is labor-intensive and remains deeply connected to the land.

Each year, during the late summer harvest season, the fruit is hand-picked from wild Opuntia engelmannii cacti in the open desert.

Harvesting requires skill and patience, as workers use tongs to carefully pluck the ripe, spine-covered fruit.

Once gathered, the fruit is transported to Cheri's Tucson facility, where it is washed, steamed, and pressed to extract the vibrant magenta juice.

This juice, rich in antioxidants and taurine, serves as the base for their signature jellies, syrups, and the iconic 'cactus candy,' a chewy, gumdrop-like treat that is a favorite among tourists and locals alike.

Cheri's Desert Harvest operates with a strong commitment to sustainability and zero-waste practices.

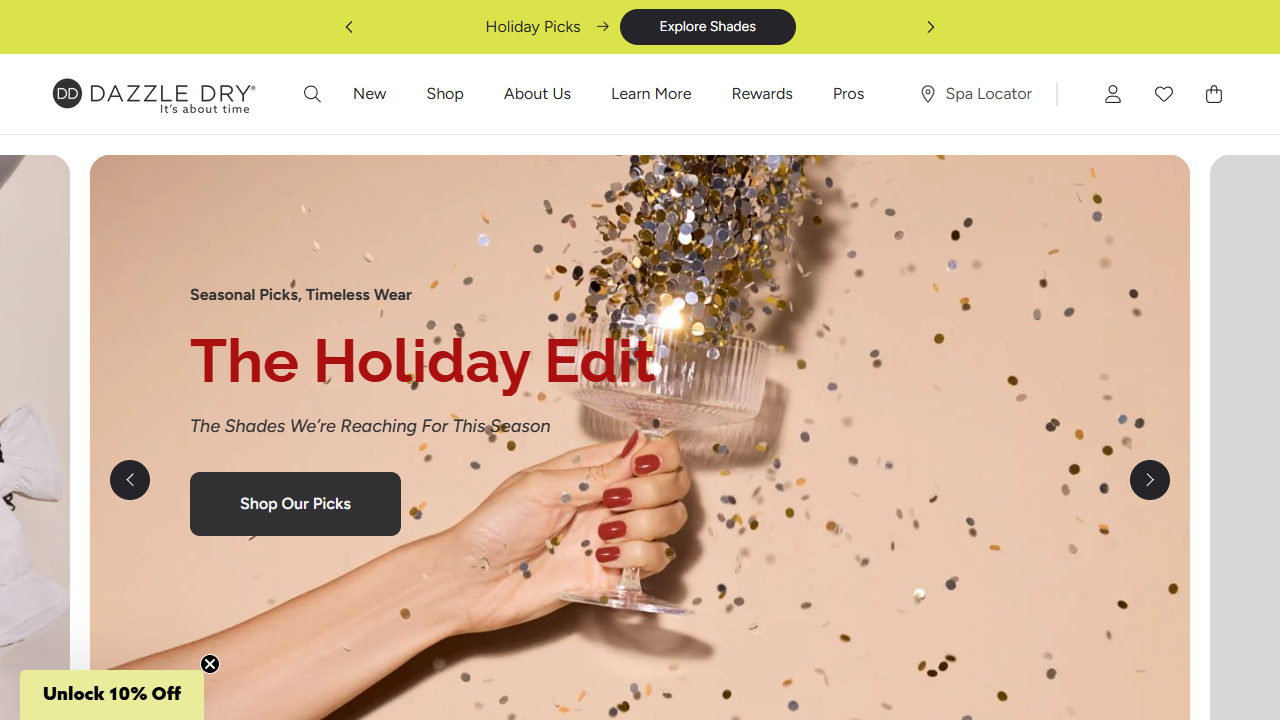

Dazzle Dry

"Long-wearing, quick-dry nail lacquer system free from harsh chemicals."

A Living Tradition

Dazzle Dry is a high-performance nail care brand manufactured by VB Cosmetics in Chandler, Arizona.

The company was founded by Dr.

Vivian Valenty, a bio-organic chemist with over 30 years of experience in the beauty industry.

Dr.

Valenty sought to solve the primary complaints associated with traditional nail polish—long drying times, short wear duration, and the use of toxic chemicals—without resorting to the UV-cured gel polishes that can damage the nail bed and require harsh soaking for removal.

The result was Dazzle Dry, a proprietary system that dries completely rock-hard in just five minutes without the use of UV lamps and lasts up to two weeks chip-free.

The Art of Handcrafted Excellence

The manufacturing takes place in a state-of-the-art, 40,000-square-foot facility in Chandler, where the company maintains strict control over formulation and production.

The science behind Dazzle Dry is unique; it utilizes a nitrocellulose-free formula, which prevents the yellowing of nails often caused by traditional polishes, and is free from common toxins such as formaldehyde, toluene, DBP, camphor, and formaldehyde resin.

Instead, it relies on flexible polymers that expand and contract with the natural nail, preventing the micro-cracks that lead to chipping.

The system is designed to be used as a four-step process: Nail Prep, Base Coat, Lacquer, and Top Coat.

One of the brand's key innovations is the use of a base coat that remains rubbery and flexible on the nail, acting as a shock absorber.

Cosanti Originals

"Hand-cast bronze and ceramic wind bells designed by architect Paolo Soleri."

The Story Behind the Brand

Cosanti Originals creates distinctive bronze and ceramic wind bells that double as architectural sculptures.

The studio is located in Paradise Valley, Arizona, at the historic residence and sculpture studio of Paolo Soleri, the visionary Italian-American architect who coined the term 'arcology' (architecture + ecology).

Established in the mid-1950s, Cosanti—a name derived from the Italian words 'cosa' (thing) and 'anti' (against), signifying a stance against materialism—remains an active foundry where artisans continue to produce Soleri's designs using his original techniques.

Innovation Meets Craftsmanship

The manufacturing process is a fascinating display of elemental craft known as earth-casting.

For the bronze bells, the process begins outdoors in the studio's 'Foundry Apse.' Artisans prepare a mold by carefully carving intricate, organic designs directly into a bed of leveled silt or sand.

Once the negative image is carved, molten bronze, heated to over 2,200 degrees Fahrenheit, is poured into the earth molds.

As the metal cools and hardens, it takes on the texture of the silt, giving each bell a rugged, organic surface that makes it unique.

After cooling, the bells are excavated from the ground, cleaned, and treated with a patina to accelerate the aging process, resulting in the signature verdigris and bronze hues.

Ceramic bells are produced using a similar slip-casting method in silt molds.

Zinger Bats

"Professional-grade custom maple, ash, and birch baseball bats."

The Story Behind the Brand

Zinger Bats is a premier manufacturer of wood baseball bats based in Chandler, Arizona.

Founded in 1998 by Kelly Eastman and now led by Scott Hanish, the company has grown from a small local operation into a brand swung by some of the biggest names in Major League Baseball.

The company's philosophy centers on durability and performance, catering to players who demand professional-grade equipment.

Zinger Bats specializes in custom production, allowing players to choose their wood type, model, length, weight, and finish.

The manufacturing process begins with the selection of the highest quality timber—Rock Maple, Northern Ash, and Birch—sourced primarily from the Northeastern United States where the cold climate produces denser, stronger wood.

The Art of Handcrafted Excellence

Once the wood splits (billets) arrive in Chandler, they are allowed to acclimate to the Arizona climate, a crucial step that stabilizes the wood before turning.

The bats are then precision-turned on computer-controlled lathes to exact specifications, ensuring consistency across every bat produced.

After turning, each bat is hand-sanded, bone-rubbed (a process that compresses the wood fibers to increase density and pop), and finished with high-quality paints or stains.

A signature step in their process is the laser engraving of the player's name and the Zinger logo, followed by the application of their distinctive adhesive sticker.

Zinger Bats is not just for professionals; they offer the same 'Pro Stock' quality to amateur players and youth leagues, making them a highly coveted gift for aspiring athletes.