Six Stories, One Golden State

"From Sausalito's ceramic kilns to Santa Ana's surf shops—discover the artisans keeping California's manufacturing heritage alive."

Where Innovation Meets Heritage

California has always been a place where dreams are crafted into reality. In the workshops and studios scattered across this vast state, a new generation of makers is redefining what it means to 'Made in USA.' From the mid-century modern ceramics that graced American tables for decades, to the surf shorts that have weathered countless waves, these six brands represent the soul of California craftsmanship. Each story is different—some born from necessity, others from vision—but all share a common thread: an uncompromising commitment to quality, community, and the belief that what we make matters.

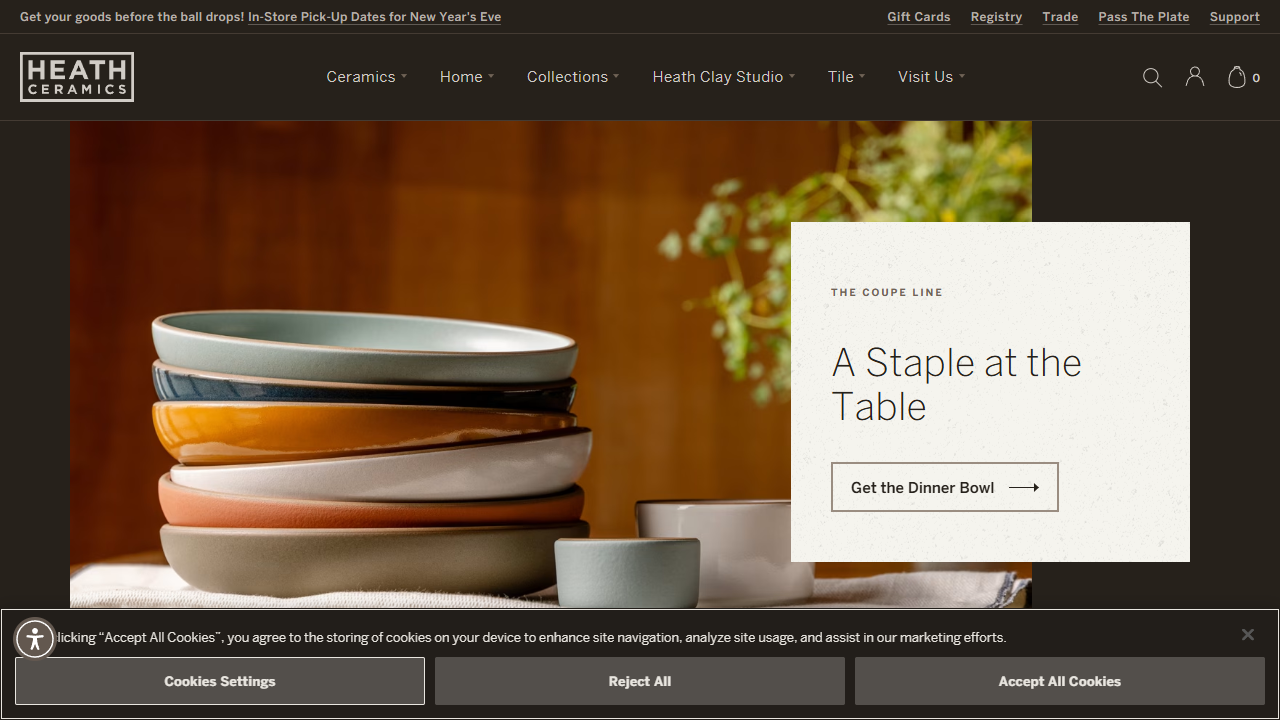

Heath Ceramics

"Mid-century modern handcrafted ceramic dinnerware and architectural tile."

From a Radical Idea to American Tables

In 1948, Edith Heath walked into a ceramics studio in Sausalito with a radical idea: what if we could see the clay itself, instead of hiding it beneath layers of glaze? A trained chemist and self-taught potter, Edith understood that clay had its own beauty—the subtle speckles, the natural variations, the way light danced across its surface.

She spent years perfecting a clay body that could fire at lower temperatures yet retain remarkable durability.

The result was the "Coupe" line, a dinnerware set so timeless that American families still set their tables with it today, 75 years later.

The Dance of Clay, Fire, and Human Hands

Walking into Heath's Sausalito factory feels like stepping into a time capsule—and yet, everything here points to the future.

Each piece begins its life as raw clay mixed with water, churned for two hours in a blunger until it becomes a smooth, workable slurry.

This slurry is then pumped into a hydraulic press, where air bubbles are squeezed out and the clay is formed into perfect cylinders called "pugs." But it's what happens next that separates Heath from mass production: every single piece is shaped by hand using techniques called "jiggering" and "jollying," where a skilled artisan guides a rotating mold against a softened clay form.

The clay dries slowly, is trimmed by hand, then receives its signature glaze—applied in such thin layers that the clay's natural character peeks through like sunlight through leaves.

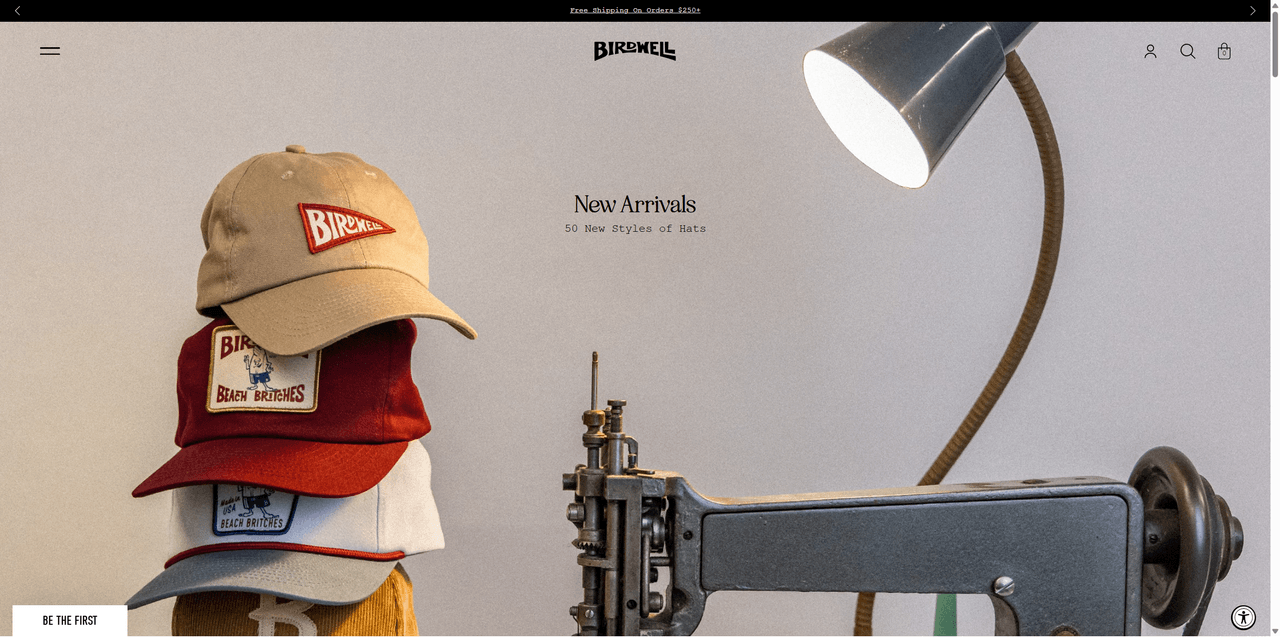

Birdwell Beach Britches

"Legendary two-ply nylon boardshorts built for durability and surf heritage."

The Birth of California Surf Culture

It was 1961, and Carrie Birdwell Mann was watching lifeguards struggle with cotton shorts that fell apart in the salt and sand.

Working from her home in Newport Beach, she started cutting and sewing prototypes in her kitchen, experimenting with heavier fabrics that could take a beating.

The breakthrough came when she discovered a durable nylon material—strong enough for workwear, light enough for the water.

Those first pairs were crude, but they worked.

Soon, lifeguards, surfers, and waterman across Southern California were asking for 'Birdies.' What started as a local solution became a symbol of authentic California surf culture.

Built to Last, One Stitch at a Time

Step into Birdwell's Santa Ana workshop today, and you'll find the same philosophy that guided Carrie: no shortcuts.

Every pair of Birdies begins as rolls of SurfNyl—a proprietary two-ply nylon fabric that's incredibly durable, quick-drying, and gets better with age.

The fabric is hand-cut in the traditional way, piece by piece, allowing for the subtle variations that make each pair unique.

Then comes the sewing: double-needle stitching throughout, reinforced stress points, and a lace-up waistband that's become iconic.

But here's what makes Birdies special—they're designed to break in.

Like a well-worn leather jacket or a favorite pair of jeans, these shorts mold to your body, becoming more comfortable with every wave, every surf session, every adventure.

Wies Made

"Farm-to-fabric premium denim and knitwear sourced and sewn entirely in the USA."

Tracing Every Thread Back to America

Nic Wiessler grew up in the Bay Area watching his grandfather work in a textile mill, seeing firsthand how American manufacturing once thrived.

When he left for college, that mill was gone—closed, outsourced, forgotten.

Years later, working in fashion, he was shocked to discover that a simple t-shirt could involve farms in Texas, factories in Vietnam, and distribution centers in Los Angeles—with everyone in between taking a cut.

He wondered: what if we went backwards? What if we made clothes the way they used to be made, but with the transparency we deserve? Wies Made was born from that question—a commitment to trace every thread, from American cotton fields to your closet.

From American Fields to Your Closet

At Wies Made, traceability isn't a buzzword—it's a daily practice.

They work directly with family farms in Texas and California, building relationships that go beyond price per pound.

The cotton is ginned, spun, and woven in American mills using traditional methods like broken twill weaving (which prevents the leg twist common in mass-produced denim).

The fabric then travels to family-owned cutting rooms in Los Angeles and sewing shops in Petaluma, where skilled artisans transform bolts of cloth into garments.

No shortcuts, no mysteries—just honest work, from dirt to shirt.

City Threads

"Sensory-friendly, 100% cotton clothing for children with sensitive skin."

Clothing That Feels Like a Hug

Joe Willis remembers the day his son came home from school, tearful because the tag in his shirt felt like 'tiny knives.' As a parent of a child with Sensory Processing Disorder, Joe knew this struggle firsthand.

Together with his partner Shayna Samuels—both deeply rooted in LA's garment district, with family histories stretching back generations in the industry—they wondered: why should parents choose between cute clothes and comfortable clothes? Why should kids with sensitive skin settle for boring garments? City Threads was their answer: beautiful, well-made clothes that feel like a hug.

Designed for Comfort, Crafted with Care

Every City Threads garment begins with a simple question: how will this feel on a child's skin? They source 100% cotton from trusted American suppliers, then pre-wash it multiple times to ensure softness from day one.

The construction is thoughtful: flat seams that won't irritate, tag-free labels printed directly on the fabric, and colors achieved through low-impact dyes that are gentle on skin and environment.

Most importantly, they make everything right here in Los Angeles, in the same neighborhood where Joe's grandfather once cut patterns and Shayna's grandmother sold fabric.

It's not just about clothes—it's about keeping tradition alive while solving real problems for real families.

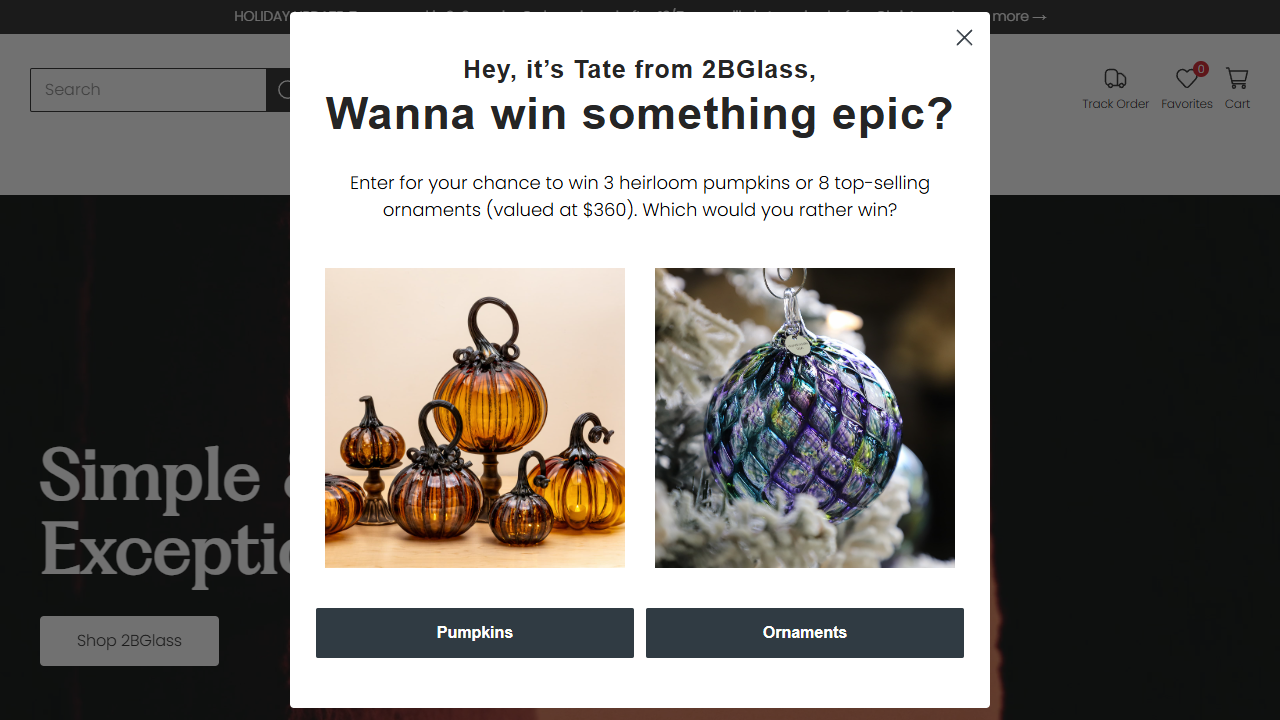

2B Glass

"Exquisite hand-blown glass pumpkins and seasonal ornaments."

Where Fire Meets Imagination

Tate and Aaron Bezdek spent years working in large glass factories, watching skilled craftspeople reduce ancient art to mass production.

They loved the material—glass is unlike any other, requiring breath, gravity, and fire to bend to your will.

But they missed the personal connection, the conversation between maker and material.

So they left the big shops, moved to Cameron Park, and built their own studio.

2B Glass isn't about output—it's about exploring what glass can become when it's shaped by human hands, one breath at a time.

Molten Glass Takes Shape

Glassblowing begins at 2,100°F, where sand becomes molten lava in the studio's 1,000-pound furnace.

This furnace runs 24/7, 365 days a year, because glass doesn't wait for convenient schedules.

When the brothers gather a glob of molten glass on the end of a blowpipe, the real conversation begins.

They shape it with tools that haven't changed in centuries—jacks, paddles, blocks—using breath and centrifugal force to coax the glass into form.

Their famous pumpkins are a perfect example: each is unique, blown free-hand without molds, with the artist making hundreds of tiny decisions that determine its final character.

No two pumpkins are exactly alike, because no two moments of creation are the same.

Green Toys

"Eco-friendly children's toys made from 100% recycled milk jugs."

Turning Waste into Wonder

Robert Von Goeben had a simple question that puzzled the toy industry: if milk jugs are safe enough for babies to drink from, why aren't they safe enough for babies to play with? In 2007, most toys were made from new plastic, often with mysterious chemical cocktails.

Robert wanted to prove that toys could be both safer and more sustainable.

He started small—just a recycling truck—made entirely from milk jugs collected in California.

But that first truck sparked a revolution.

Today, Green Toys has diverted millions of milk jugs from landfills, proving that 'waste' is just a resource in the wrong place.

The Recycling Revolution

The magic of Green Toys happens before the toys are even made.

Milk jugs arrive at their facility, where they're inspected, cleaned, and shredded into tiny flakes—think of it as giving plastic a second life.

These flakes are then melted down and reprocessed into food-safe plastic pellets, indistinguishable from virgin plastic in quality but completely different in origin.

The pellets are mixed with mineral-based colorants (no heavy metals, no BPA, no phthalates) and injection-molded into toy parts.

Here's the beautiful part: the toys snap together without glue, screws, or metal axles.

When a child outgrows them, they can be recycled again, continuing the cycle.