Island Craftsmanship

"In the Pacific's embrace, Hawaii makers blend ancient wisdom with modern innovation."

Aloha Spirit in Manufacturing

Hawaii's manufacturing tradition is as unique as its islands. Isolated by 2,500 miles of ocean, Hawaii cannot rely on heavy raw material imports for low-margin goods due to shipping costs. Instead, 'Made in Hawaii' focuses on provenance—the idea that value comes from the land itself or the culture. The concept of Omiyage (gift-giving) is a powerful economic driver in Hawaii, sustaining a market for premium consumables. The brands featured here represent the diversity of Hawaii's manufacturing: chocolate-dipped macadamia nut cookies, authentic Aloha wear, bean-to-bar chocolate, premium ukuleles, island-inspired fashion, and botanical skincare. Each product carries the spirit of aloha: harmony, balance, deep respect for nature, and the understanding that what we make should honor the land and traditions that shaped us.

Big Island Candies

"Chocolate-dipped macadamia nut shortbread cookies with Omiyage gift packaging."

A Living Tradition

Big Island Candies was founded in 1977 in Hilo, Hawaii, and is widely credited with inventing the chocolate-dipped macadamia nut shortbread cookie.

The company's success is built on the Japanese-Hawaiian tradition of 'Omiyage' (gift giving), where travelers bring back high-quality, beautifully packaged gifts for friends and family.

Their manufacturing facility in Hilo is a major attraction, designed with glass walls to allow visitors to watch the baking and chocolate-dipping processes.

They use 100% pure Kona coffee and locally grown macadamia nuts, integrating Hawaii's agricultural outputs into a shelf-stable, exportable luxury product.

Unlike many confectioners that use compound coatings, Big Island Candies uses premium high-grade chocolate.

The brand is synonymous with quality and is a staple gift for holidays and corporate events in Hawaii.

Their commitment to Hilo is absolute; despite global demand, they have kept their production centralized to ensure quality control and community employment.

The Art of Handcrafted Excellence

The confectionery production process at Big Island Candies begins with sourcing the finest ingredients: 100% pure Kona coffee and locally grown macadamia nuts.

The shortbread cookies are baked in industrial ovens using traditional recipes that produce the signature texture—crisp yet tender, with a delicate crumb that melts in your mouth.

The chocolate-dipping process is the company's signature technique; cookies are transported through a tempering machine where they receive a precise coating of premium chocolate, then are placed on cooling belts where the chocolate sets at the perfect temperature and shine.

Each cookie is hand-dipped diagonally to showcase the cookie beneath, a design element that has become iconic.

The packaging process is engineered specifically for the Omiyage market—rigid, beautiful boxes designed to protect the fragile cookies during long flights.

Quality control is rigorous at every stage, from ingredient testing to final packaging inspection.

The Hilo facility serves as both factory and destination, with visitors able to observe the production through floor-to-ceiling windows.

This transparency validates the 'Made in Hawaii' claim and justifies the premium price point.

The company's vertical integration—from ingredient sourcing to final packaging—ensures complete quality control and supports the local agricultural economy.

Sig Zane Designs

"Authentic Aloha wear with hand-cut cultural prints inspired by Hawaiian flora and fauna."

A Living Tradition

Sig Zane Designs, based in Hilo on the Big Island of Hawaii, is a premier designer of authentic Aloha wear.

Founded in 1985 by Sig and Nalani Kanakaʻole, the brand is deeply rooted in Native Hawaiian culture, specifically the traditions of hula and chant.

Unlike mass-market Aloha shirts which are often produced offshore, Sig Zane's garments are designed, cut, and sewn with a focus on local production and cultural integrity.

The designs feature specific indigenous flora and fauna, serving as wearable lessons in Hawaiian botany and history.

The company operates a flagship store in downtown Hilo that is a destination for both locals and visitors.

Their manufacturing philosophy prioritizes the 'Aloha Aina' (love of the land) spirit, ensuring that the commercial product honors the culture it represents.

Sig Zane Designs has collaborated with major global brands (like Tiffany & Co.) but maintains its core operations in Hilo.

The shirts are considered ceremonial attire by many in Hawaii, worn for weddings, government functions, and formal events, distinguishing them from tourist-grade souvenirs.

The Art of Handcrafted Excellence

The design and manufacturing process at Sig Zane Designs begins with cultural research and artistic inspiration drawn from Hawaiian traditions.

Sig Zane and his team study indigenous plants, animals, and cultural motifs, creating original designs that tell specific stories of the islands.

These designs are hand-cut and printed using specialized techniques that ensure authentic representation of Hawaiian culture.

The printing process uses high-quality fabrics and eco-friendly inks that preserve the vibrant colors and detailed patterns.

Cutting and sewing operations are performed locally in Hawaii by skilled artisans who understand the nuances of Aloha wear construction.

Each garment is carefully constructed to ensure proper fit and drape, with attention to details like pocket placement, button selection, and seam finishing.

Quality control involves checking color accuracy, pattern alignment, and construction quality.

The company's limited release strategy creates scarcity and hype, with new designs often selling out quickly.

This approach contrasts sharply with mass-produced 'Hawaiian shirts' made overseas.

The packaging emphasizes sustainability and cultural authenticity, often featuring information about the specific plants or stories depicted in the design.

Sig Zane's commitment to keeping production local ensures that the Aloha wear aesthetic remains authentic and supports the local economy.

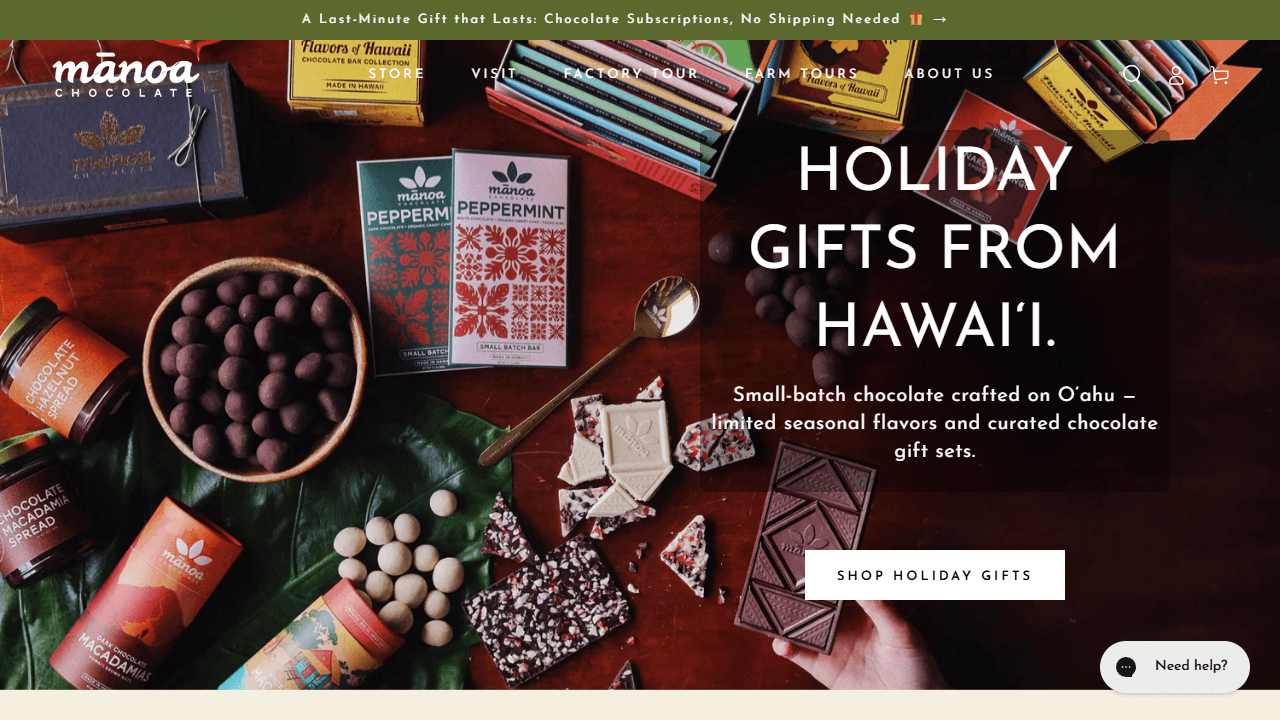

Mānoa Chocolate

"Bean-to-bar chocolate from Hawaiian-grown cacao with reforestation mission."

Innovation Born from Necessity

Mānoa Chocolate, located in Kailua, Oahu, is a pioneer in the American bean-to-bar chocolate movement.

Hawaii is the only state in the U.S.

with a climate suitable for commercial cacao cultivation, allowing Mānoa to produce chocolate that is domestically grown and manufactured—a rarity in the confectionery world.

Founded in 2010, the company sources cacao directly from local farmers across the Hawaiian islands (including the Hamakua Coast and Maunawili Valley) as well as ethically sourced global beans.

Their manufacturing process involves small-batch roasting, winnowing, grinding, and tempering in their Kailua factory.

Mānoa Chocolate is committed to 'Aloha Aina', using their business to support the reforestation of Hawaii with cacao trees.

Their packaging is biodegradable and features designs by local artists.

The flavor profiles of their chocolate reflect the unique terroir of volcanic soil, often described as having fruit-forward and floral notes.

They offer factory tours to educate consumers on the cacao-to-chocolate process, further establishing the value of their premium pricing.

Innovation Meets Craftsmanship

The chocolate-making process at Mānoa Chocolate begins with sourcing cacao pods from local farms across Hawaii, including partnerships with growers on the Hamakua Coast and Maunawili Valley.

The cacao beans undergo fermentation in controlled conditions, a critical step that develops the complex flavor compounds unique to Hawaiian chocolate.

After fermentation, beans are dried to optimal moisture levels, then transported to the Kailua factory for roasting.

The roasting process uses custom profiles for each origin, highlighting the distinctive characteristics of Hawaiian terroir.

Winnowing separates the cacao nibs from shells, which are carefully inspected for quality.

The nibs are ground using stone melangeurs, a slow process that generates heat through friction, developing the chocolate's flavor and texture.

During conching, the chocolate is agitated for hours to achieve smooth texture and remove unwanted volatiles.

Tempering is critical for snap and sheen; chocolate is carefully heated, cooled, and reheated to form stable crystals.

The finished chocolate is molded into bars using specialized equipment, then cooled in controlled environments.

Each batch is small-scale, allowing for precise quality control.

The packaging process emphasizes sustainability with biodegradable materials and locally sourced artwork.

Factory tours educate visitors about the entire process, from cacao pod to finished bar.

The company's reforestation efforts integrate environmental stewardship into the business model, making chocolate a vehicle for ecological restoration.

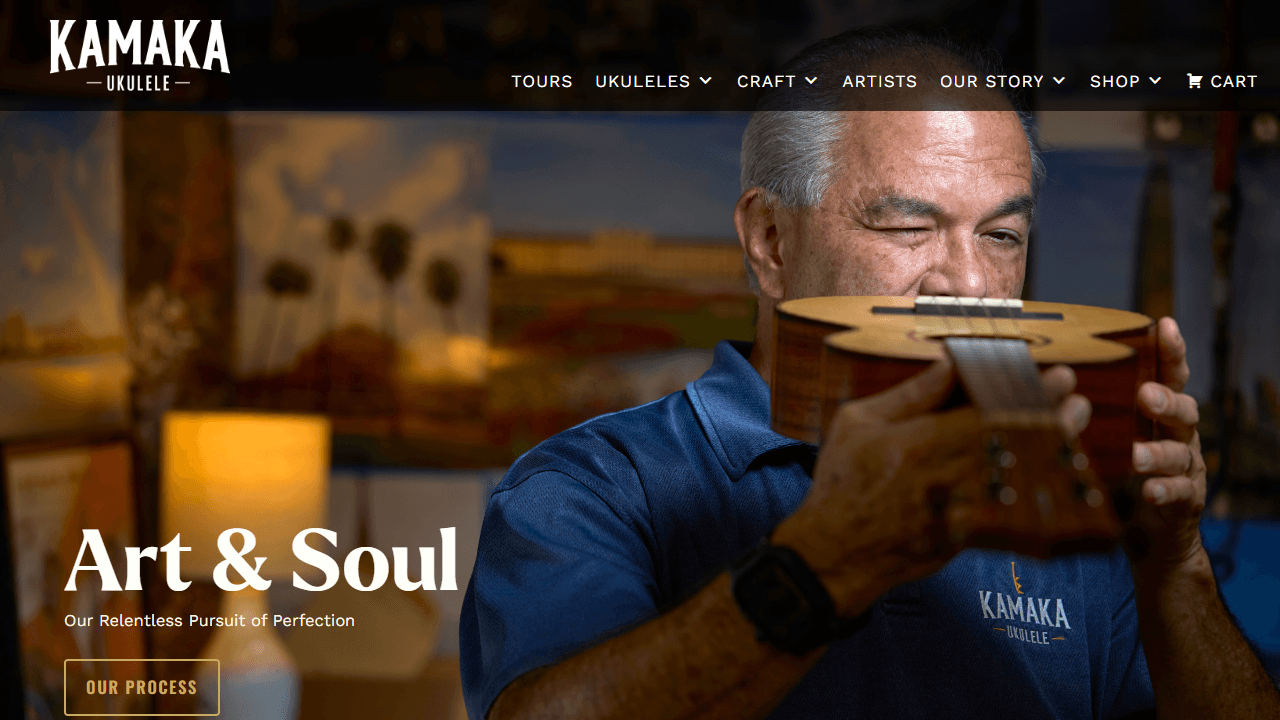

Kamaka Ukulele

"Premium koa wood ukuleles, inventing the pineapple design in 1928."

A Living Tradition

Kamaka Ukulele is the world's most prestigious ukulele manufacturer, founded in 1916 by Sam Kamaka in Honolulu.

The company is credited with inventing the 'Pineapple' ukulele in 1928, a patented oval body shape that produces a distinct, mellow resonant sound.

Kamaka instruments are handcrafted primarily from Hawaiian Koa wood, a native timber revered for its tonal qualities and beauty.

The manufacturing process is a multi-generational family tradition; the company is currently led by the third generation of the Kamaka family.

The process involves meticulous wood selection, natural aging (sometimes for years) to ensure stability, and precise hand-assembly.

The 'KK' logo on the headstock is recognized globally as a mark of excellence.

Due to the scarcity of Koa wood and the labor-intensive production, Kamaka ukuleles are considered heirloom investments rather than mere instruments.

They represent the pinnacle of Hawaii's craft manufacturing, blending indigenous materials with a century of luthier expertise.

The factory in Kaka'ako remains a pilgrimage site for musicians worldwide.

The Art of Handcrafted Excellence

The ukulele-making process at Kamaka begins with the careful selection of Koa wood, sourced from sustainable forests across Hawaii.

Each piece of wood is inspected for grain pattern, color, and tonal potential, then stacked and aged—sometimes for years—to achieve optimal moisture content and stability.

The wood is cut using traditional saws and modern CNC equipment, with each instrument requiring multiple pieces of wood for the top, back, sides, and neck.

The most skilled luthiers handle the precise carving of the soundboard and back, work that requires years of training to perfect.

The distinctive pineapple shape is achieved through specialized templates and hand-shaping techniques.

Sound hole rosettes are meticulously inlaid, often using traditional materials and patterns.

Neck construction involves precise joinery and fretting, with each fretwire carefully placed and leveled.

The assembly process requires careful attention to detail, with components fitted by hand to ensure perfect resonance.

Finishing involves applying multiple coats of lacquer, hand-sanded between coats, to achieve the mirror-like finish that has become a Kamaka hallmark.

Final setup includes stringing, intonation adjustment, and play-testing by master luthiers.

Each instrument receives the 'KK' headstock logo and serial number.

The quality control process is exhaustive; no instrument leaves the factory without passing rigorous standards for tone, playability, and construction.

This combination of traditional craft and modern precision control ensures that each Kamaka ukulele is an heirloom-quality instrument.

Allison Izu

"Petite-fit contemporary island wear designed and made in Hawaii."

A Living Tradition

Allison Izu is a Honolulu-based fashion brand founded by Allison Izu to address a critical gap in the market: clothing designed specifically for petite women (5'6" and under).

The brand has since evolved to offer inclusive sizing while maintaining a 'Made in Hawaii' ethos.

Allison Izu is a staunch advocate for local manufacturing, keeping her design, cutting, and sewing operations within the state to support the local fashion industry.

This adherence to local production is challenging in an island economy where fabrics must be imported, but it allows for high ethical standards and rapid response to fashion trends.

The brand's aesthetic blends contemporary fashion with an island lifestyle sensibility—clothes that are professional yet comfortable for Hawaii's tropical climate.

Allison Izu is frequently featured in local business accelerators like Mana Up, which supports Hawaii-based product companies scaling for export.

Her inclusion in national gift guides highlights the growing recognition of Hawaii's fashion industry beyond traditional resort wear.

Time-Honored Techniques

The fashion design and production process at Allison Izu begins with pattern development specifically for petite proportions, a specialization that sets the brand apart in the market.

Fabrics are carefully selected for Hawaii's climate—breathable, wrinkle-resistant materials that maintain their shape in humidity.

While some fabrics must be imported due to Hawaii's island location, the brand maximizes local value-add through design, cutting, and sewing operations in Honolulu.

The cutting process utilizes specialized equipment that minimizes fabric waste while ensuring precise pattern matching.

Sewing operations employ skilled local artisans who understand the nuances of tropical garment construction—flat-felled seams for durability, strategic ventilation, and comfortable fit.

Quality control is integrated throughout production, with each garment inspected at multiple stages.

The brand's small-batch production model allows for flexibility and quick turnaround on new designs.

Packaging emphasizes sustainability and local connection, often featuring information about the inspiration behind each piece.

Allison Izu's commitment to local manufacturing supports the Hawaii fashion industry and ensures ethical labor practices.

The brand's participation in programs like Mana Up provides resources for scaling while maintaining local roots.

This approach demonstrates how 'Made in Hawaii' can thrive in categories beyond traditional souvenirs, creating premium fashion that reflects the islands' contemporary lifestyle.

Ua Body

"Botanical skincare using kukui nut oil, coconut, and royal Hawaiian sandalwood."

The Founder's Vision

Ua Body is a skincare company based in Waimea on the Big Island of Hawaii, continuing a legacy started 30 years ago as 'Island Herbal'.

The brand focuses on clean, additive-free skincare that harnesses the power of native Hawaiian botanicals.

Their products feature ingredients like Kukui nut oil, Coconut oil, and Royal Hawaiian Sandalwood (Iliahi), which is sourced from sustainable forests on the Big Island.

Ua Body's manufacturing is small-batch and handcrafted, ensuring the potency and freshness of the natural ingredients.

The brand positions itself as a provider of 'La'au Lapa'au' (Hawaiian herbal medicine) in a modern, luxurious format.

Their packaging is minimalist and eco-friendly, utilizing glass and paper to reduce plastic waste.

Ua Body represents the 'wellness' sector of Hawaii's export economy, offering a sensory connection to the islands through scent and touch.

They are a notable success story of the Mana Up accelerator program, which helps Hawaii brands scale globally while maintaining local roots.

The Art of Handcrafted Excellence

The skincare production process at Ua Body begins with sourcing botanicals from trusted suppliers across Hawaii, including kukui nuts from sustainable groves, coconuts from local farms, and sandalwood from regulated forests on the Big Island.

The manufacturing process emphasizes small-batch production to ensure ingredient potency and freshness.

Kukui nuts are cold-pressed to extract oil using traditional methods that preserve beneficial compounds.

Coconut oil is processed using minimal refinement to maintain its natural properties.

Sandalwood is steam-distilled to capture its aromatic compounds, a process that requires expertise to achieve the signature scent.

The blending process involves carefully combining oils and botanical extracts at specific temperatures to maintain their beneficial properties.

No synthetic preservatives or additives are used, relying instead on natural antimicrobial agents like vitamin E.

Products are hand-bottled using glass containers, with labels made from recycled paper and soy-based inks.

Quality testing ensures microbiological safety while maintaining the natural integrity of the products.

The packaging process emphasizes sustainability, using minimal materials and avoiding plastic wherever possible.

Each batch is logged and tracked to ensure consistency and traceability.

The company's commitment to small-batch production means products are made to order, ensuring maximum freshness.

The manufacturing facility in Waimea is designed to be transparent, often hosting visitors who want to learn about natural skincare production.

This approach connects consumers directly to the source of their skincare products.