Crossroads of American Craft

"From Indianapolis's racing heritage to Fort Wayne's manufacturing plants—discover the brands that keep Indiana moving."

Where Precision Meets Purpose

Indiana has always been America's crossroads, where innovation travels as freely as goods on the National Road. In the factories of Indianapolis, engineers perfect the engines that power NASCAR. In Columbus, architects design buildings that define city skylines. In Indianapolis, pharmaceutical scientists develop medicines that save lives. This is the Crossroads of America, and the brands born here understand what that means: your reputation travels as far as your products. Whether it's Cummins' diesel engines that power trucks across the continent, Allison Transmission's gearboxes that move military vehicles into battle, or Eli Lilly's medicines that treat diseases worldwide, Indiana companies build things that matter. They combine Midwestern practicality with world-class expertise, creating products trusted by professionals everywhere.

Cummins

"Global power solutions leader manufacturing diesel and alternative fuel engines."

Innovation Born from Necessity

Clessie Lyle Cummins and William Irwin founded Cummins Engine Company in 1919 in Columbus, Indiana, with a vision to build the best diesel engines in the world.

What began in a small garage has grown into a global powerhouse that powers everything from pickup trucks to cargo ships to backup generators that keep hospitals running.

Cummins has remained headquartered in Columbus, Indiana, building a world-class engineering and manufacturing campus in a small Midwestern town.

The company's success comes from relentless innovation and an unwavering commitment to reliability.

Today, Cummins engines can be found in vehicles and equipment on every continent, proving that American engineering can compete—and win—anywhere in the world.

A Commitment to Quality

Building a Cummins engine is a masterpiece of precision engineering.

It begins with casting engine blocks from molten iron in foundries that operate at over 2,500°F.

These blocks are machined to tolerances measured in thousandths of an inch, ensuring perfect fit for pistons, rods, and bearings.

Assembly happens on carefully orchestrated production lines where engines are built by technicians who specialize in specific components.

Each engine undergoes extensive testing, including dynamometer runs that simulate real-world conditions.

Cummins uses advanced materials like compacted graphite iron for strength and durability.

The company's engineering teams continuously innovate, developing cleaner-burning engines that meet strict emissions standards while maintaining the power and reliability Cummins is known for.

Indiana Bell

"Historic telecommunications company building America's communications infrastructure."

The Story Behind the Brand

Indiana Bell was part of the Bell System that connected America through telecommunications, operating throughout Indiana and parts of neighboring states.

The company played a crucial role in building the infrastructure that allowed Indiana businesses and families to communicate across the state and beyond.

Indiana Bell's operators, engineers, and technicians built the networks that enabled economic growth throughout the Hoosier State.

While telecommunications has evolved dramatically since Indiana Bell's founding, the company's legacy lives on in the modern telecommunications networks that continue to connect Indiana to the world.

Indiana Bell represents the foundation of America's digital infrastructure.

The Art of Handcrafted Excellence

Building telecommunications infrastructure requires laying thousands of miles of cable, installing switching equipment, and maintaining networks that operate 24/7.

Indiana Bell's technicians worked to connect homes and businesses to the telephone network, installing lines and ensuring reliable service.

The company's switchboard operators were the human interface of the telecommunications system, personally connecting calls and solving problems for customers.

Engineering teams designed network expansions, planned cable routes, and ensured the system could handle growing demand.

Quality control meant maintaining clear connections and minimal downtime.

Every aspect of service required attention to detail and commitment to customer satisfaction.

Allison Transmission

"World's largest manufacturer of fully automatic transmissions for medium- and heavy-duty vehicles."

Innovation Born from Necessity

James A.

Allison founded Allison Transmission in 1915 in Indianapolis, starting with racing transmissions that could withstand the brutal conditions of the Indianapolis Motor Speedway.

The company's experience building race-car transmissions led to innovations in commercial vehicle transmissions, creating the world's first fully automatic transmission for trucks in 1948.

Today, Allison transmissions are found in vehicles from garbage trucks to school buses, military vehicles to motorhomes.

Based in Indianapolis, the company employs thousands of engineers, technicians, and production workers who understand that their transmissions keep America moving.

Allison's commitment to innovation means they're continuously developing new technologies that make vehicles more efficient, reliable, and capable.

A Commitment to Quality

Building an Allison transmission is a precision operation that combines advanced engineering with skilled craftsmanship.

The process begins with machining cast-iron and aluminum housings to extremely tight tolerances, ensuring perfect alignment of internal components.

Gears, shafts, and clutches are manufactured using specialized equipment and inspected using coordinate measuring machines.

Assembly happens on production lines where technicians carefully install components, following detailed work instructions.

Each transmission undergoes comprehensive testing, including dynamometer runs that simulate thousands of miles of operation.

Allison uses advanced materials and heat treatments to ensure durability.

The company's engineering team continues to innovate, developing hybrid systems and electric drives for next-generation vehicles.

Eli Lilly

"Global pharmaceutical company developing life-changing medicines for over 145 years."

Innovation Born from Necessity

Colonel Eli Lilly founded Eli Lilly and Company in 1876 in Indianapolis with a simple mission: create the highest quality medicines and get them to patients who need them.

What began as a small pharmacy has grown into one of the world's leading pharmaceutical companies, developing treatments for diabetes, cancer, autoimmune diseases, and more.

Lilly has remained headquartered in Indianapolis for nearly 150 years, building a campus that's both a workplace and a symbol of Indiana's commitment to innovation.

The company's success comes from combining world-class science with a deep understanding that patients are counting on them.

Every medicine developed in Indianapolis has the potential to change lives around the world.

A Commitment to Quality

Pharmaceutical manufacturing requires the highest standards of quality and precision.

Eli Lilly's process begins with research in state-of-the-art laboratories, where scientists work to understand disease biology and identify potential drug targets.

Once a promising compound is identified, it undergoes extensive testing in laboratories and clinical trials involving thousands of patients.

Manufacturing uses specialized equipment to produce medicines in facilities that meet strict regulatory requirements.

Every step is documented and controlled, from raw material testing to final packaging.

Eli Lilly uses advanced manufacturing techniques like continuous manufacturing, where medicine is produced as a steady stream rather than in batches.

Quality control is integrated into every step, ensuring that patients receive safe, effective medicines.

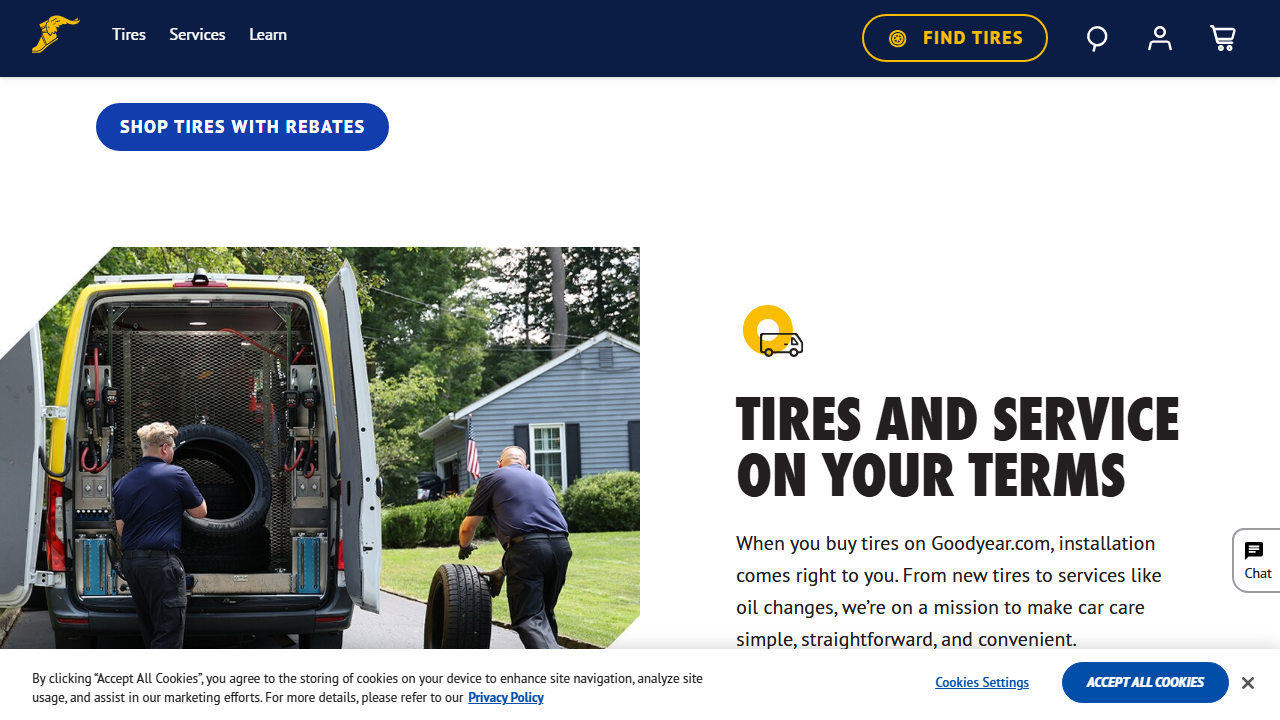

Goodyear Tire & Rubber

"Historic tire manufacturer building quality tires for vehicles worldwide."

Innovation Born from Necessity

Goodyear's Danville, Indiana plant represents the company's long commitment to American manufacturing and innovation.

The plant produces a wide range of tires for trucks, buses, and off-road vehicles, using techniques developed over more than a century of tire manufacturing.

Goodyear understands that a tire isn't just rubber—it's a sophisticated composite of steel, fabric, and chemical compounds that must work together to provide safety, performance, and durability.

The Danville facility employs skilled workers who take pride in building tires that keep America's vehicles moving safely.

Every tire produced in Indiana must meet Goodyear's exacting standards, ensuring that whether it's mounted on a delivery truck or an emergency vehicle, it performs reliably in all conditions.

A Commitment to Quality

Tire manufacturing is a complex process that transforms raw materials into precision-engineered products.

It begins with mixing rubber compounds—natural and synthetic rubber, carbon black, chemicals, and sulfur—using internal mixers that blend them into a uniform compound.

The rubber is then formed into components: tread, sidewall, and body plies.

Steel cords and fabric belts are coated with rubber, creating the tire's structure.

Assembly happens on tire-building machines where components are layered precisely, then shaped into a green tire.

The green tire is vulcanized in molds at high temperature and pressure, creating the final tire with its distinctive tread pattern.

Every tire is inspected for quality before shipping.

Studebaker

"Historic American automobile manufacturer with a legacy of innovation (1902-1966)."

The Founder's Vision

The Studebaker Brothers started making wagons in South Bend, Indiana in 1852, building the wagons that carried pioneers west on the Oregon Trail.

When automobiles began replacing horses, Studebaker was perfectly positioned to make the transition.

The company built its first automobile in 1902, combining wagon-making expertise with automotive innovation.

Studebaker was known for building quality cars at reasonable prices, with a design aesthetic that was distinctly American.

The company continued innovating until production ended in 1966, introducing features like electric headlights, automaticDirectionals, and overhead valve engines.

While Studebaker no longer builds cars, their legacy lives on in collector communities worldwide and in the automotive designs that influenced the industry.

Innovation Meets Craftsmanship

Studebaker's automotive manufacturing process evolved from its wagon-making expertise, applying woodworking and metalworking skills to new materials.

The company used high-quality steel and hardwoods, building bodies that were both durable and beautiful.

Production involved stamping steel panels, assembling bodies on wooden jigs, and installing mechanical components sourced from the best suppliers.

Studebaker was known for innovations like unitized body construction, where the body and frame were integrated for greater strength.

The company's South Bend factory employed thousands of skilled workers, from engineers to painters to final assembly technicians.

Every Studebaker was built with pride, representing the culmination of the company's journey from wagons to automobiles.