Bluegrass Craftsmanship

"From horse country to coal country, Kentucky makers honor tradition."

Bluegrass Quality

Kentucky's manufacturing tradition is steeped in tradition. From the horse farms of the bluegrass to the bourbon distilleries of the bourbon trail, from the coal mines of the east to the agricultural centers, Kentucky's makers understand that quality takes time. The brands featured here represent the diversity of Kentucky's manufacturing: heritage ceramics dating back to 1815, educational craft programs, modern artisan pottery, leather goods for the digital age, bourbon-barrel aged soy sauce, and the legendary regional soft drink Ale-8-One. Each product carries Kentucky's DNA: respect for heritage, commitment to quality, and the understanding that what we make should honor the land and traditions that shaped us.

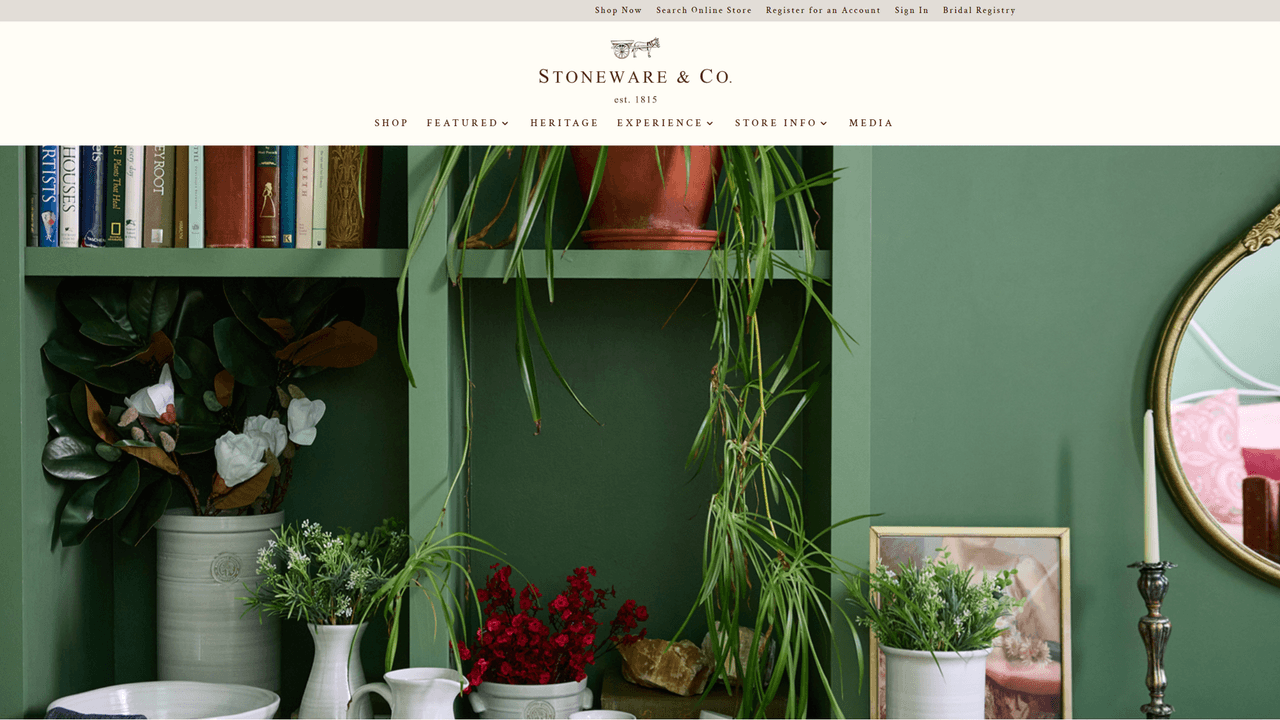

Stoneware & Co.

"Heritage stoneware ceramics made in Louisville since 1815."

The Story Behind the Brand

Stoneware & Co.

(formerly Louisville Stoneware) stands as one of the oldest stoneware manufacturers in the United States, with a lineage that dates back to 1815.

Located in the Paristown Pointe neighborhood of Louisville, the company is a survivor.

It has weathered the Civil War, the Great Depression, and the offshoring boom of the 1990s, remaining a steadfast producer of American ceramics.

The manufacturing process at Stoneware & Co.

is a testament to the materiality of Kentucky.

The company utilizes 2,500 tons of clay annually, harvested from the rich deposits of Western Kentucky.

This clay is processed in-house—cleaned, pugged, and de-aired—giving the company total control over the ceramic body.

The Art of Handcrafted Excellence

The factory floor is not automated in the modern sense; it is a hub of skilled manual labor.

Forming: Artisans use a variety of techniques including wheel-throwing, slip-casting, and jiggering (a process where a profile tool shapes the clay over a rotating mold) to create plates, bowls, and crocks.

Decorating: The hallmark of the brand is its hand-painted decoration.

Artists apply glazes with brushes, creating patterns like the 'Bachelor Button' or 'Bluegrass.' Because this is done by hand, every piece has slight variations—a 'fingerprint' of the artist.

Firing: The ware is fired in industrial kilns at high temperatures, vitrifying the clay so that it becomes non-porous and chip-resistant.

This durability is key to its value proposition; these are not fragile curiosities but functional kitchenware designed for daily use.

Berea College Student Craft

"Student-made brooms, textiles, and woodcraft supporting education."

A Living Tradition

Berea College Student Craft is unique in the landscape of American manufacturing.

It is not a private for-profit entity but a program within Berea College, the first interracial and coeducational college in the South.

Founded in 1855, the college requiring students to work charges no tuition, in campus labor programs to earn their keep.

The Student Craft program, originally 'Fireside Industries,' was established in 1893 to preserve Appalachian craft traditions and provide students with skilled labor opportunities.

The manufacturing at Berea is divided into dedicated studios, each preserving a specific craft lineage.

Broomcraft: Perhaps the most iconic of Berea's products, the brooms are hand-wound using broomcorn (sorghum vulgare).

Students learn to dye the broomcorn in vibrant colors—reds, greens, purples—and wind it onto handles using a foot-treadle machine.

The Art of Handcrafted Excellence

The broom-making process begins with selecting quality broomcorn and dyeing it in vibrant colors using traditional techniques.

Students operate foot-treadle machines to wind the colored broomcorn onto wooden handles in a 'Shaker' style braid.

This process is physically demanding and results in a tool that is both functional and sculptural.

Weaving: The weaving studio utilizes fly-shuttle looms to produce textiles like placemats, runners, and baby blankets.

The program has a history of high production but has since refocused on artisanal quality and complex patterns.

Woodcraft: Utilizing sustainably harvested timber from the college's own forest, students create furniture and traditional games.

The 'Skittles' game is a perennial best-seller, a wooden board game that has been a staple of Kentucky childhoods for generations.

When a consumer buys a Berea broom or blanket, they are buying a narrative of social justice and education.

The proceeds go back into the college's operating fund, supporting the tuition-free mission.

Dirty South Pottery

"Modern ceramic mugs and tableware featuring Kentucky-inspired designs."

The Founder's Vision

Dirty South Pottery represents the new generation of Kentucky makers.

Founded in 2012 by Carvel and Ashley Norman, who met while studying art at Eastern Kentucky University, the business began in a home studio before expanding to a brick-and-mortar location in Winchester, KY.

The name 'Dirty South' is a playful nod to their location and the messy nature of working with clay.

While smaller than Stoneware & Co., Dirty South Pottery operates a sophisticated production studio.

They utilize electric kilns and wheels to produce thousands of pieces annually.

The division of labor plays to the founders' strengths: Carvel focuses on throwing forms (mugs, bowls) and developing glazes, while Ashley handles the surface decoration and business operations.

The Art of Handcrafted Excellence

The pottery-making process begins with mixing clay bodies to achieve the perfect plasticity and firing characteristics.

The clay is wedge to remove air bubbles and ensure consistency.

Forming: Carvel throws forms on the potter's wheel, creating mugs, bowls, and vases with consistent wall thickness and smooth surfaces.

The pieces are allowed to dry to leather-hard state before being trimmed to remove excess clay and create clean foot rings.

Decoration: Ashley handles surface decoration, applying underglazes and slips to create distinctive patterns and designs.

Their 'This Might Be Bourbon' mug is a masterclass in product positioning—it capitalizes on the global obsession with Kentucky bourbon without dealing with the regulatory headaches of selling alcohol.

It turns a simple ceramic vessel into a statement piece.

Firing: Pieces are fired in electric kilns to cone 6 (2232°F), vitrifying the clay and setting the glazes.

The final step involves quality inspection and packaging for shipment to customers.

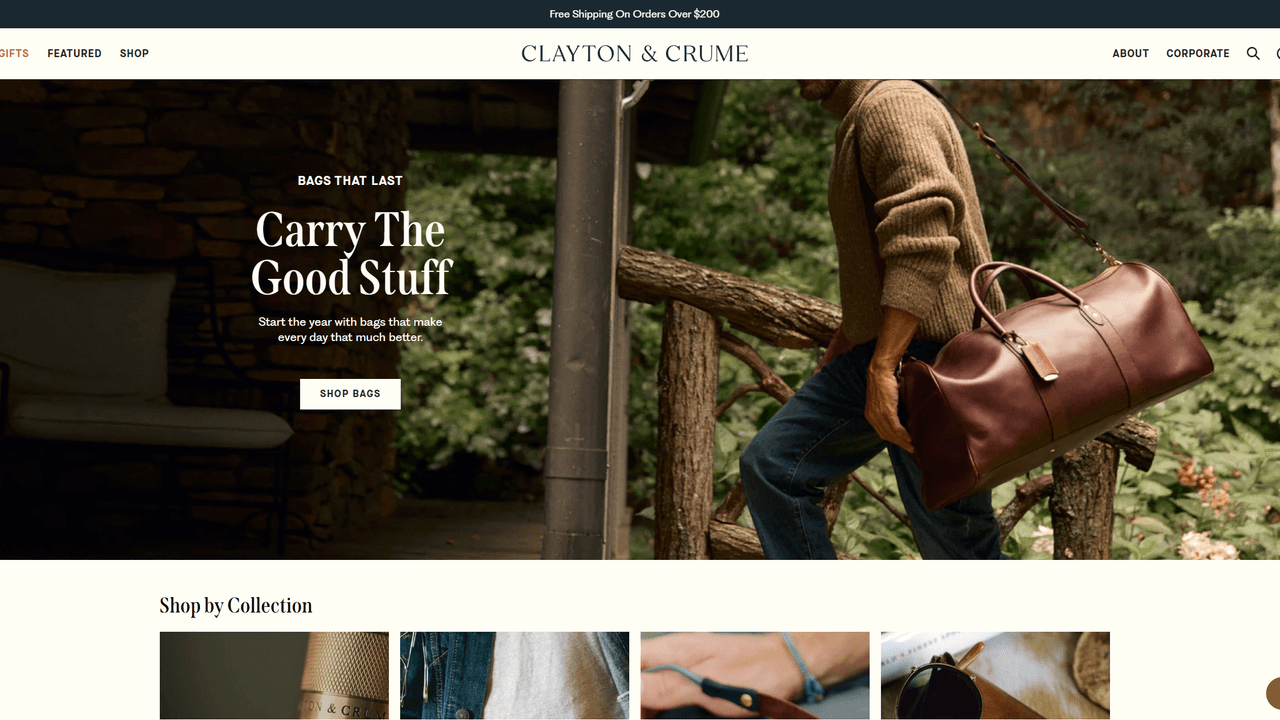

Clayton & Crume

"Handcrafted leather goods with monogramming and bourbon lifestyle accessories."

The Story Behind the Brand

Clayton & Crume fits the archetype of the 'digital native vertical brand' (DNVB).

Founded in a dorm room at Western Kentucky University in 2012 by Clay and Crume, the brand was born from a desire to upgrade the cheap promotional merchandise often found on college campuses.

They identified leather—a material synonymous with Kentucky's equestrian culture—as their medium.

The company operates a workshop in Louisville where the majority of their goods are produced.

A critical component of their manufacturing model is customization.

They have integrated monogramming into their production line, allowing for rapid personalization of belts, wallets, and keyfobs.

This turns a standard accessory into a highly personal gift, making them a favorite for groomsmen gifts and corporate awards.

The Art of Handcrafted Excellence

The leather goods manufacturing process begins with sourcing premium hides from American tanneries.

The hides are inspected for quality and imperfections before being cut into pattern pieces using traditional leatherworking techniques.

The cutting process requires skill to optimize grain placement and minimize waste.

Construction involves stitching using heavy-duty sewing machines and hand-finishing techniques.

Edge finishing is done by hand, burnishing edges with beeswax to create smooth, durable surfaces.

The monogramming process uses laser engraving technology to personalize products with names, initials, or custom messages.

Their 'Rocks Glass' wrapped in leather is a direct accessory to the bourbon lifestyle, reinforcing the state's brand identity.

Unlike traditional workshop models, Clayton & Crume is built for scale, utilizing sophisticated digital marketing, paid social media, and SEO to reach a national audience.

Their growth demonstrates that 'Made in USA' brands can compete in the fast-paced e-commerce landscape if they leverage technology alongside tradition.

Bourbon Barrel Foods

"Bourbon-barrel aged soy sauce and bourbon-smoked spices."

A Living Tradition

Bourbon Barrel Foods, founded by Matt Jamie in 2006, is a culinary outlier.

It is the only soy sauce microbrewery in the United States.

Jamie, a chef with no prior manufacturing experience, identified a unique opportunity: to merge the ancient Asian tradition of soy brewing with Kentucky's bourbon heritage.

The manufacturing process is a marvel of cross-industry resource utilization.

The company sources non-GMO soybeans and soft red winter wheat—the same wheat used in many bourbon mash bills—from local Kentucky farmers.

After the brewing and fermentation process, the soy sauce is aged in retired bourbon barrels.

The bourbon barrel is not just a container; it is an active ingredient.

The char on the inside of the barrel, and the 'devil's cut' (the bourbon trapped in the wood), impart a smoky, oaky, and slightly sweet flavor to the soy sauce.

Time-Honored Techniques

The soy sauce production begins with soaking and steaming non-GMO soybeans and wheat, creating the base for fermentation.

The mixture is inoculated with koji spores, which convert starches to sugars.

After fermentation, the mash is pressed to extract the liquid, which becomes soy sauce.

The unique step is aging: the soy sauce is transferred to retired bourbon barrels where it ages for months, absorbing the flavors of the wood and residual bourbon.

This aging process imparts the signature smoky, oaky flavor that distinguishes their soy sauce from Asian varieties.

The company has vertically integrated its 'bourbon' narrative by expanding into spices.

They purchase used barrel staves, grind them down, and use the smoke to flavor salt, pepper, sugar, and paprika.

This 'Bourbon Smoked' line allows them to create comprehensive gift baskets that offer a 'taste of Kentucky.' Each product is carefully crafted to capture the essence of bourbon while maintaining the functionality of traditional condiments and spices.

Ale-8-One

"Legendary ginger and citrus soft drink bottled in Kentucky since 1926."

A Living Tradition

Ale-8-One (a pun on 'A Late One') is a ginger and citrus soft drink that has been bottled in Winchester, KY, since 1926.

It is the only soft drink invented in Kentucky that is still in existence.

For decades, it was a hyper-regional product, available only in central Kentucky, which created a cult-like following among locals.

The company remains family-owned (the Fielding family) and operates its bottling plant in Winchester.

The 'secret recipe' is still hand-mixed by the family before being sent to the production line.

The manufacturing challenge for Ale-8-One has been balancing this heritage with the need for novelty.

To compete with global beverage giants, they have introduced new flavors like 'Orange Cream' and 'Blackberry,' and notably a 'Pawpaw' flavor.

The Art of Handcrafted Excellence

The beverage production process begins with sourcing high-quality ingredients including fresh ginger, citrus oils, and natural flavorings.

The secret recipe is hand-mixed by family members in small batches, maintaining consistency and quality control.

The mixture is combined with carbonated water and carefully blended to achieve the perfect balance of ginger spice and citrus brightness.

The bottling process uses modern filling equipment while maintaining the classic glass bottle packaging that enhances the retro brand aesthetic.

Quality control includes testing for carbonation levels, flavor consistency, and clarity.

While a soft drink might seem an unusual gift, Ale-8-One is frequently packaged in crate sets or paired with bourbon for 'Kentucky Mules.' For the Kentucky diaspora living elsewhere, a bottle of Ale-8 is a powerful symbol of home.

The glass bottles and retro branding enhance its giftability, positioning it as a premium craft soda rather than a commodity beverage.