Chesapeake Bay Craftsmanship

"From the Bay to the mountains, Maryland makers work with maritime tradition."

Bay State Quality

Maryland's manufacturing tradition is written on the water. From the crab shacks of the bay to the shipyards of Baltimore, from the tobacco farms of the south to the tech centers of the north, Maryland's makers understand that diversity is strength. The brands featured here represent the diversity of Maryland's manufacturing: heritage food brands that have operated for over a century, modern wave of maker brands born from economic resilience, precision instruments crafted for artists, and outdoor products designed for suburban life. Each product carries Maryland's DNA: maritime heritage, culinary excellence, and the innovative spirit of the Chesapeake region.

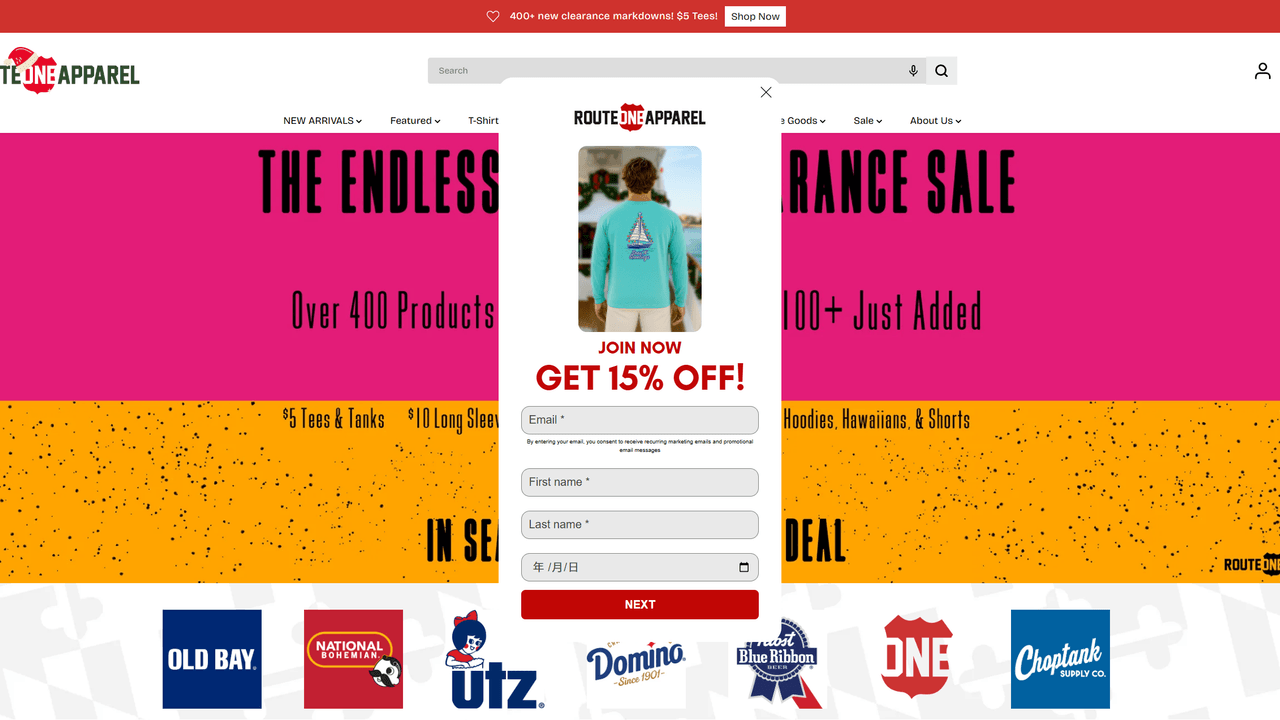

Route One Apparel

"Maryland Flag and Old Bay themed clothing celebrating state pride."

The Founder's Vision

Route One Apparel is the definitive case study of the 'State Pride' apparel movement.

Founded in 2010 by Ali von Paris while she was still a student at the University of Maryland, the company began as a reaction to a singular event: the closing of a popular local bar.

Von Paris designed a commemorative t-shirt, and the overwhelming demand revealed a latent market for hyper-local, identity-driven clothing.

What started in a dorm room has expanded into a multi-million dollar enterprise that serves as the unofficial outfitter of Maryland.

The brand's narrative is deeply intertwined with Maryland's unique iconography—specifically the Calvert and Crossland arms of the state flag and the pervasive culture of Old Bay seasoning.

Von Paris capitalized on the 'cult of Maryland,' recognizing that Marylanders possess an unusually high affinity for their state symbols.

In 2025, the brand was acquired by MD-Brand, a family-owned distributor, ensuring its continued operation within the state and expanding its production capabilities.

How It's Made

While many apparel brands outsource entirely, Route One Apparel maintains a hybrid model with significant local value addition.

The company operates a robust logistics and design headquarters in Towson, Maryland.

Following the acquisition by MD-Brand, operations are integrated with a facility that boasts the largest screen printing and embroidery capacity in the Baltimore area.

This allows for rapid prototyping and production of custom runs, a critical capability for responding to viral trends such as sports championships or local memes.

The company utilizes direct-to-garment and direct-to-film digital printing technologies, enabling high-fidelity reproduction of complex designs like the Maryland flag on various substrates.

Route One Apparel products range from practical items like face masks and scarves to novelty products like Crabcake onesies and 'Old Bay' scented apparel.

The brand has secured official licensing agreements with other heritage Maryland brands like McCormick (Old Bay), Utz, and National Bohemian beer, creating a synergy that reinforces the authenticity of the products.

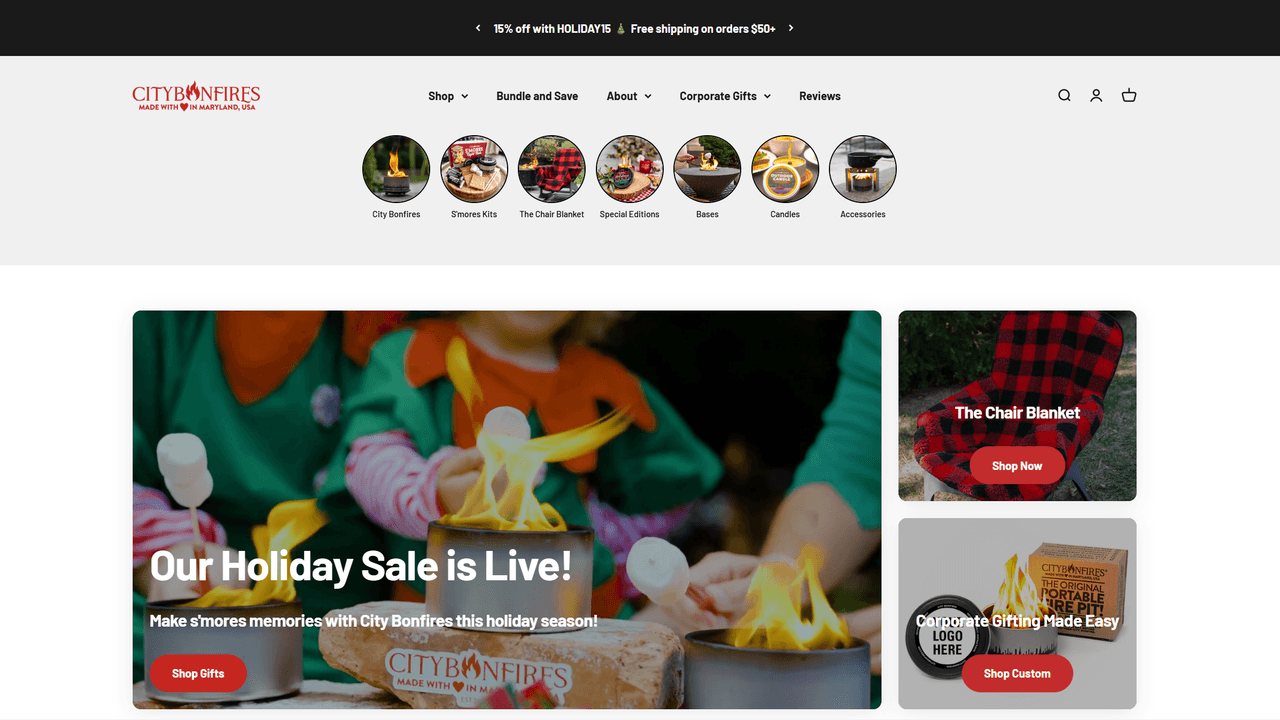

City Bonfires

"Portable mini fire pits for safe, smoke-free outdoor experiences."

The Founder's Vision

City Bonfires serves as a primary example of American ingenuity in the face of adversity.

Founded in 2020 by Chris McCasland and Michael Opalski, two fathers living in Maryland, the company was born directly from the economic fallout of the COVID-19 pandemic.

Both founders saw their primary income sources in the events and restaurant industries evaporate.

Confined to their homes and seeking safe ways to socialize outdoors with their families, they identified a gap in the market: traditional fire pits were too large, expensive, and smoky for casual suburban or urban use.

Working out of McCasland's garage, they prototyped a solution using recyclable metal tins, soy wax, and eco-friendly briquettes.

The result was a 'bonfire in a can'—portable, safe for roasting marshmallows, and smoke-free.

The narrative of 'two dads in a garage' resonated powerfully with consumers and media alike, propelling the brand to viral status on TikTok and leading to features on Good Morning America and NPR.

The Art of Handcrafted Excellence

Despite scaling to sell over one million units, City Bonfires maintains a commitment to domestic manufacturing.

The product is handmade in Maryland, using non-toxic materials sourced within the US.

The manufacturing process involves the precise pouring of soy wax and the arrangement of proprietary briquettes to ensure a consistent 3-5 hour burn time.

The transition from a garage operation to a warehousing facility in Rockville illustrates the scalability of micro-manufacturing when supported by digital marketing and national retail partnerships like REI and Tractor Supply.

City Bonfires has secured a permanent spot in the 'giftable' market due to its low price point (typically under $30) and high utility.

It is marketed as an 'experience' gift—perfect for date nights, apartment balconies, or camping.

The introduction of 'S'mores Kits' bundles the fire pit with chocolate, graham crackers, and marshmallows, creating a complete gift solution that requires no additional shopping.

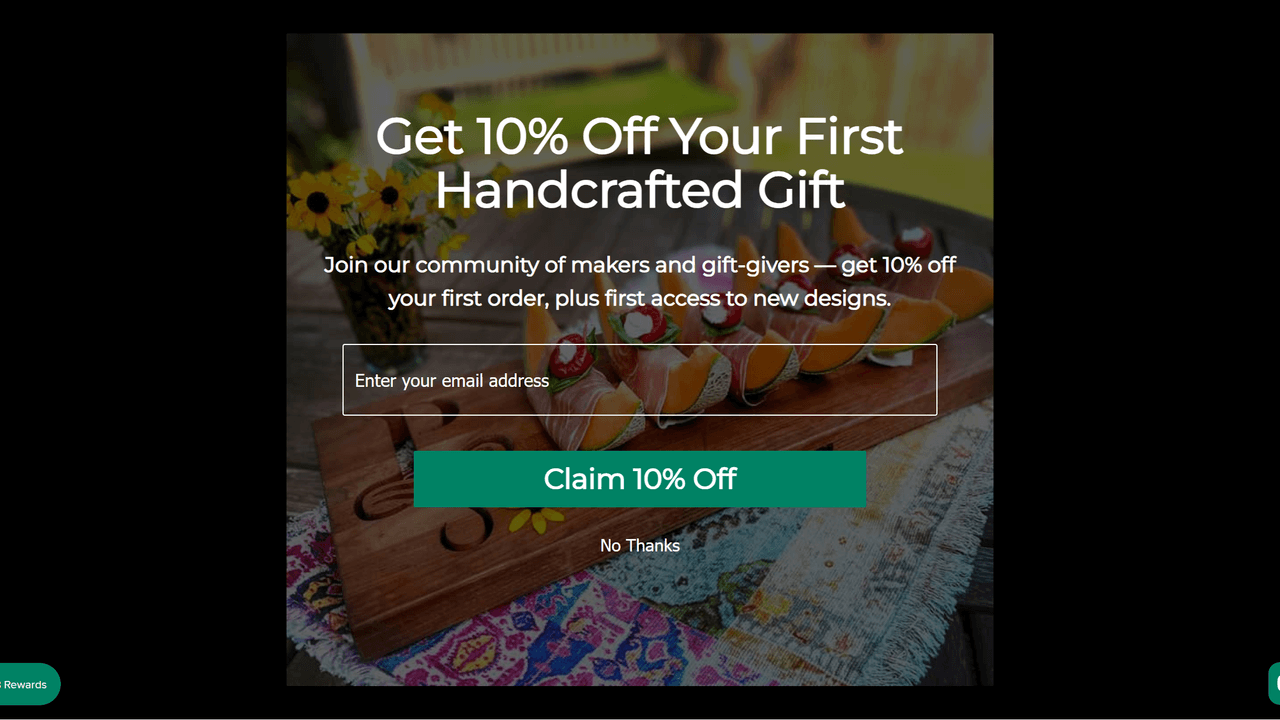

Words with Boards

"Personalized cutting boards crafted with scroll-sawn letter art."

The Founder's Vision

Words with Boards revitalizes the concept of personalized home goods through subtractive manufacturing.

Founders Kim Strassner and Mike Pararas launched the business in 2013 from the basement of their Baltimore rowhouse.

The inspiration came from a high school woodshop project of Kim's—a cutting board she had made for her mother.

Seeking a unique gift for friends, they utilized leftover butcher block from a kitchen renovation to recreate the concept.

The brand gained national prominence after being selected as a finalist in Martha Stewart's 'American Made' design contest and subsequently appearing on Oprah's 'Favorite Things' list in 2015.

This media exposure accelerated their growth, forcing a move from their basement to a 3,000-square-foot design studio and woodshop in Baltimore's Hampden neighborhood.

Innovation Meets Craftsmanship

The distinguishing feature of Words with Boards is their manufacturing technique.

Unlike the vast majority of personalized wooden products which rely on laser engraving (burning the wood), Words with Boards utilizes scroll saws to physically cut the letters out of the wood.

This 'negative space' design requires significantly more skill and labor but results in a cleaner, more sculptural aesthetic.

The company exclusively uses sustainably forested American hardwoods—primarily Maple, Cherry, and Walnut.

Furthermore, they have integrated a sustainability initiative where a tree is planted in the US for every product sold, closing the ecological loop.

The boards are positioned as 'heirloom' gifts, suitable for weddings, anniversaries, and housewarmings.

The ability to customize the board with names, dates, or phrases makes each item unique.

The narrative of Baltimore craftsmanship, combined with the validation from Martha Stewart and Oprah, allows the brand to command a premium price point compared to mass-market alternatives.

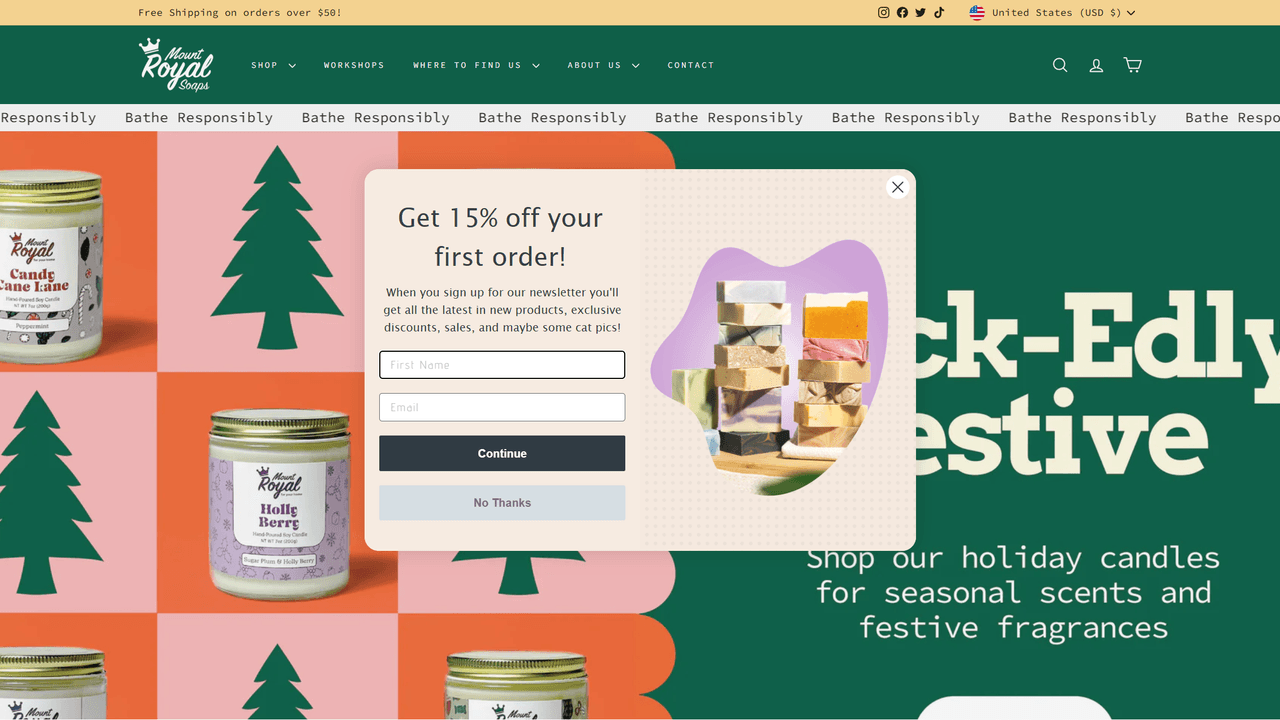

Mount Royal Soaps

"Sugar scrubs and bar soaps made with clean, sustainable ingredients."

The Founder's Vision

Mount Royal Soaps represents the intersection of social enterprise and manufacturing.

Founded in 2014 by three friends—Matt, Pat, and Sam—the company's origin is rooted in recovery.

All three founders were newly in recovery from alcohol and drug addiction and sought a constructive, creative outlet.

Soap making became that outlet, evolving from a hobby into a mission-driven business.

The company is named after Mount Royal Avenue in Baltimore, grounding it geographically in the city's history.

During the COVID-19 pandemic, the company demonstrated the agility of local manufacturing by rapidly pivoting to produce hand sanitizer for the community when industrial supplies failed, an action that solidified their reputation as a community pillar.

A Commitment to Quality

The company operates a manufacturing facility in the Woodberry neighborhood of Baltimore, just miles from their retail storefront in Remington.

They adhere to strict 'clean' manufacturing principles: no palm oil, no synthetic fragrances, and no animal testing.

The production is small-batch, allowing for rigorous quality control of their sugar scrubs, solid shampoo bars, and lotions.

Mount Royal Soaps appeals to the ethical consumer.

The products are packaged with sustainability in mind, often using plastic-free or compostable materials.

The 'Sugar Scrub' line is a particular favorite in gift guides, noted for its high quality and reasonable price point (~$17).

The story of the founders' recovery adds a layer of social impact to the purchase, making it a powerful gift for those who value corporate responsibility.

Fisher's Popcorn

"Hand-mixed caramel popcorn made in copper kettles since 1937."

The Story Behind the Brand

Fisher's Popcorn is an institution on the Maryland Eastern Shore.

The company was founded in 1937 by Everett Fisher, who brought his popcorn expertise from Philadelphia to the Ocean City boardwalk.

The story goes that Fisher's former employer vanished with the recipes, forcing Everett to engineer his own caramel formulation—one he believed was superior.

He opened his stand at the corner of Talbot Street and the Boardwalk, where it remains today.

Fisher's manufacturing process is a deliberate preservation of 1930s methods.

The popcorn is cooked in open copper kettles, a material essential for precise temperature control during the sugar caramelization process.

Unlike industrial continuous-flow cookers, Fisher's utilizes batch processing where the caramel, popcorn, and butter are mixed by hand.

This labor-intensive method ensures that every kernel is evenly coated.

While they have expanded into a wholesale facility to supply grocery stores, the core product remains 'small batch' by design.

The Art of Handcrafted Excellence

The popcorn-making process begins with air-popping premium kernels to achieve the perfect light, fluffy texture that serves as the foundation for their caramel coating.

The secret caramel recipe is prepared in classic copper kettles, where skilled craftsmen monitor temperature and timing to achieve the perfect consistency.

The caramel is constantly stirred by hand, a technique that allows for precise control over texture and flavor development.

While the classic Caramel Popcorn is their flagship product, they have innovated with flavors that reflect the mid-Atlantic region, most notably the 'Old Bay Seasoned Caramel Popcorn,' which blends the sweet caramel crunch with the savory, spicy kick of the region's favorite crab seasoning.

The freshly coated popcorn is spread on cooling tables where it solidifies into crunchy clusters.

Each batch is packaged in iconic plastic tubs that preserve freshness and allow for easy transport.

The Ocean City location serves as a manufacturing hub where customers can watch the popcorn being made in real-time, reinforcing the transparency and authenticity of the brand.

Goetze's Candy Company

"Caramel Creams® and Cow Tales® made since 1895."

Innovation Born from Necessity

Goetze's Candy Company is one of the oldest confectionery manufacturers in the United States, operating continuously in Baltimore since 1895.

Founded by August L.

Goetze as the Baltimore Chewing Gum Company, the firm pivoted to caramel production in 1917 when R.

Melvin Goetze, Sr.

developed a non-sticky caramel recipe by incorporating wheat flour.

This innovation created the 'Caramel Cream' (or 'Bullseye'), a soft, chewy candy with a cream center that became an American staple.

The company operates out of a historic facility on East Monument Street in Baltimore, originally built in 1928 and subsequently expanded.

Goetze's is currently managed by the fifth generation of the family, a rarity in American business.

They source ingredients domestically wherever possible, with CEO Mitchell Goetze emphasizing that he 'wouldn't sleep at night' if he outsourced packaging to save money at the cost of American jobs.

Time-Honored Techniques

The factory produces millions of pounds of candy annually, utilizing specialized machinery to extrude the caramel and cream simultaneously.

Goetze's products are low-cost, high-volume gifts often used as stocking stuffers or Halloween treats.

Their longevity gives them cross-generational appeal; grandparents introduce them to grandchildren.

The 'Cow Tale,' a stick version of the caramel, is a staple of convenience store counters nationwide.

The manufacturing process involves heating and mixing caramel ingredients in large kettles, then forming the candy through extrusion machines that create the signature cream center.

Quality control is maintained through careful monitoring of temperature and timing during the cooking process.

The company maintains traditional recipes while ensuring modern food safety standards.

Packaging is done on-site, with products distributed nationally through major retailers while maintaining the iconic Baltimore-based production facility.

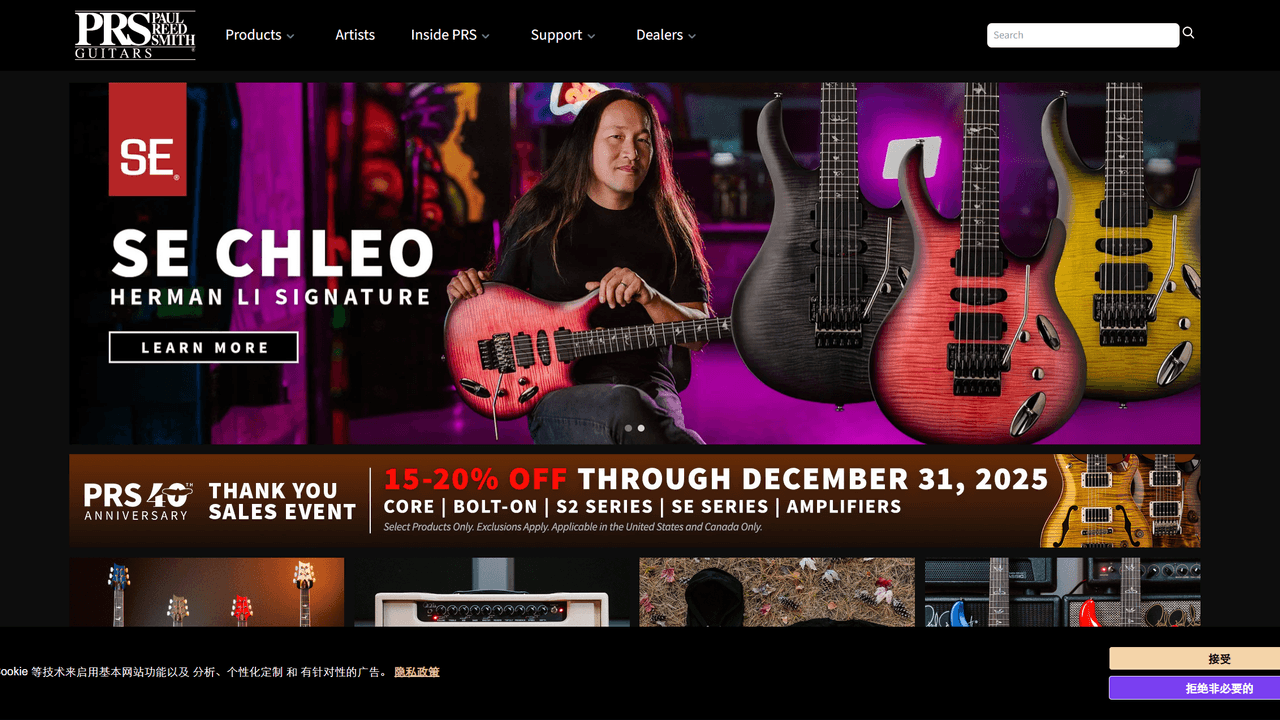

PRS Guitars

"Premium electric guitars bridging vintage aesthetics with modern reliability."

The Story Behind the Brand

Paul Reed Smith (PRS) is a central figure in American luthiery.

Starting in an attic in Annapolis in the 1970s, Smith built guitars by hand and aggressively marketed them to touring rock stars at local arenas, famously convincing Carlos Santana to adopt his instruments.

He founded PRS Guitars in 1985, aiming to bridge the gap between the aesthetic beauty of vintage instruments and modern reliability.

PRS Guitars operates a manufacturing campus in Stevensville, Maryland.

The facility is a case study in the integration of technology and craft.

CNC machines are used for the rough carving of bodies and necks to ensure consistency within thousandths of an inch, while the final sanding, fretwork, and finishing are performed by hand by skilled artisans.

The factory employs hundreds of Maryland workers and is known for its 'wood library,' where premium timbers are seasoned and selected.

The Art of Handcrafted Excellence

The guitar manufacturing process begins with selecting and seasoning premium tonewoods, including Maple, Mahogany, and exotic species.

CNC machines precision-carve the body and neck geometry, ensuring consistent fit and finish.

The assembly process involves hand-fitting components and careful attention to detail at every stage.

Neck construction utilizes traditional dovetail joints combined with modern CNC precision for optimal playability.

The fretwork—one of PRS's signature differentiators—is performed by skilled technicians who spend years mastering the craft of shaping and polishing frets to perfection.

Finishing involves applying multiple coats of catalyzed varnish, then wet-sanding and buffeting to achieve the mirror-like finish that has become a PRS hallmark.

Electronics are assembled in-house, with particular attention to pickup winding and electronic component selection.

Each guitar undergoes rigorous quality control and play-testing before leaving the facility.

A PRS guitar represents the pinnacle of 'Made in USA' quality, competing globally against Japanese and European manufacturers.

The brand also produces a range of Maryland-made accessories such as guitar straps and cables, which serve as accessible gifts for musicians.