Show-Me State Pride

"From Anheuser-Busch's brewing mastery to Bass Pro Shops' outdoor excellence—discover Missouri's tradition of excellence."

Where American Dreams Take Flight

Missouri earned its nickname 'The Show-Me State' not through politics, but through manufacturing—proving time and again that when you combine Midwestern work ethic with innovative thinking, you create products the world depends on. From the beer that fueled westward expansion to the aircraft that defend freedom, Missouri brands share a commitment to quality that speaks louder than marketing. This is the crossroads of America, where rivers converge and industries flourish, where beer flows from springs and outdoor gear is tested in pristine wilderness. In a state that bridges North and South, East and West, these six stories represent the best of American manufacturing—rooted in tradition, built for the future, and proud of its heritage.

Anheuser-Busch

"America's beer icon brewing with tradition and innovation since 1852."

The Founder's Vision

In 1852, Eberhard Anheuser and his son-in-law Adolphus Busch arrived in St.

Louis with a dream: create beer so good that it would travel the world.

They started with a simple observation: St.

Louis sat at the confluence of America's greatest rivers, with caves perfect for aging beer and access to grain from the finest farms in the Midwest.

But beer is more than ingredients—it's about craftsmanship.

When most breweries were content with adequate, Anheuser-Busch obsessed over quality.

They pioneered temperature-controlled fermentation, developed unique yeast strains, and created packaging that protected beer from light and oxygen.

When prohibition threatened their business, they pivoted, making cereal and concentrates until the 21st Amendment ended the dry years.

Through wars and recessions, the company never lost sight of its mission: brew beer of the highest quality with ingredients that reflect America's abundance.

Today, they continue to honor tradition while embracing innovation.

Time-Honored Techniques

Creating beer worthy of the Anheuser-Busch name requires a brewing process that combines time-honored techniques with modern precision.

It begins with water—St.

Louis' famously soft water that's perfect for brewing, requiring minimal treatment to achieve the ideal mineral balance.

Barley malt arrives from Midwestern farms and is mashed using a process that's been refined over generations, extracting sugars that will become alcohol.

The wort is boiled with hops that provide the signature bitterness and aroma, with precise timing that extracts optimal flavor compounds.

What makes Anheuser-Busch unique is their proprietary yeast—strains that have been cultured for over 160 years, creating consistent flavor profiles that define their beers.

Fermentation happens in stainless steel tanks at precisely controlled temperatures, where yeast converts sugars into alcohol and CO2.

The beer is then aged in facilities that maintain consistent temperatures, allowing flavors to mature and develop complexity.

Before packaging, beer undergoes rigorous quality testing: alcohol content verification, pH measurement, microbe testing, and sensory evaluation.

It's brewing where science and tradition work together to create something extraordinary.

Boeing

"Premier aerospace manufacturer building the world's most advanced aircraft."

Innovation Born from Necessity

In 1939, Boeing faced a decision: expand eastward and risk losing their Seattle base, or invest in Missouri's growing aviation industry.

They chose Missouri, and that decision changed American aerospace forever.

The St.

Louis facility became home to military aircraft development, producing everything from the B-47 Stratojet to the F-15 Eagle—planes that defended freedom and advanced aviation technology.

What made Boeing Missouri special wasn't just the aircraft they built—it was the culture of innovation that defined the workforce.

Engineers and craftspeople worked side by side, each understanding that building aircraft isn't just manufacturing—it's crafting machines that carry human lives at supersonic speeds, 30,000 feet above the earth.

Through mergers, acquisitions, and industry challenges, Boeing's Missouri facilities remain at the forefront of aerospace, building the next generation of aircraft that will take us further than we've ever gone before.

A Commitment to Quality

Building aircraft that carry passengers and cargo safely around the world requires manufacturing processes that are as precise as they are innovative.

Boeing begins with advanced materials: aluminum alloys, titanium components, and carbon fiber composites that provide strength while minimizing weight.

The manufacturing process uses techniques borrowed from aerospace engineering: robotic drilling systems that create holes with tolerances measured in thousandths of an inch, automated fiber placement for composite structures, and friction stir welding for lightweight metal joints.

Each aircraft section is built in climate-controlled environments where temperature and humidity are monitored obsessively—because even small environmental changes can affect material properties.

Assembly happens in massive buildings where overhead cranes position major components with precision.

Quality control is integrated at every step: non-destructive testing using ultrasonic and X-ray inspection, coordinate measuring machines that verify complex geometries, and flight testing that validates performance.

It's manufacturing where precision isn't just important—it's a matter of life and death.

Emerson Electric

"Global technology leader providing innovative solutions for critical industries."

The Story Behind the Brand

In 1890, John Emerson saw a problem: flour mills were losing product and productivity due to inefficient equipment.

His solution—a new design for the automatic flour mill—was so successful that he founded a company to manufacture it.

Over the next century, Emerson Electric grew from solving one industry's problems to becoming a global leader in technology solutions.

Through recessions, wars, and technological revolutions, Emerson never lost sight of its mission: create technologies that make industries more efficient, more reliable, more sustainable.

When manufacturing needed better automation, Emerson delivered.

When oil and gas required more efficient processes, Emerson innovated.

When HVAC systems needed smarter controls, Emerson answered.

Today, their technologies power data centers, manufacturing plants, and infrastructure around the world.

But at its heart, Emerson remains what it always was: a company dedicated to solving problems with practical, innovative solutions.

Because the best technology is technology that actually works.

Innovation Meets Craftsmanship

Creating technologies that power critical industries requires manufacturing processes that combine precision engineering with unwavering quality standards.

Emerson begins with component design using advanced CAD systems and simulation software that predicts performance under real-world conditions.

Manufacturing uses precision machining centers capable of creating parts with tolerances measured in millionths of an inch, ensuring that components fit together perfectly and operate smoothly.

Electronic components are assembled in clean room environments where even microscopic contamination can affect performance.

Software is developed using industry-standard methodologies with extensive testing that validates functionality before deployment.

Each product undergoes comprehensive testing: electrical testing to verify performance, environmental testing to ensure reliability in harsh conditions, and integration testing to confirm compatibility with existing systems.

Quality control is integrated throughout the process, not added at the end.

It's manufacturing where innovation meets reliability, resulting in technologies that industries can trust with their most critical operations.

Huggies (Kimberly-Clark)

"America's trusted baby care products, keeping little ones dry and comfortable."

The Story Behind the Brand

In 1968, Kimberly-Clark faced a challenge: create a disposable diaper that could compete with cloth diapers in absorbency while offering the convenience parents craved.

They had an advantage—years of experience making paper products for industrial use.

But babies aren't factories, and diaper engineering is more complex than it appears.

They needed to create a diaper that could absorb quickly, hold moisture without leakage, and fit comfortably on wiggling bodies.

The result was Huggies—diapers that didn't just work, they worked better than anything before.

What made Huggies special wasn't just technology—it was understanding that caring for babies means caring for families.

When mothers needed smaller sizes for preemies, Huggies responded.

When parents wanted more natural materials, Huggies innovated.

Today, they continue to advance diaper technology, but always with the same goal: keep babies dry, comfortable, and happy.

Because every baby deserves the best care possible.

The Art of Handcrafted Excellence

Creating diapers that can handle a baby's needs requires a manufacturing process that's part chemistry, part engineering, and part artistry.

It begins with the core—wood pulp fibers that are processed to create absorbent cores capable of holding many times their weight in liquid.

Super-absorbent polymers are added to the pulp, materials that can absorb 100x their weight in water, transforming liquid into a gel that won't leak.

The core is wrapped in a top sheet designed to pull moisture away from baby's skin, keeping them dry even during long naps.

Leg cuffs made from elastic materials ensure a snug fit without leaving marks.

The outer layer uses breathable films that prevent leaks while allowing air circulation.

Assembly happens on high-speed lines where precision is critical—components must align perfectly, adhesives must bond securely, and quality checks must catch any imperfection.

Testing is extensive: absorbency testing, fit testing on real babies (with parental consent!), and leak testing under various conditions.

It's manufacturing where precision meets care.

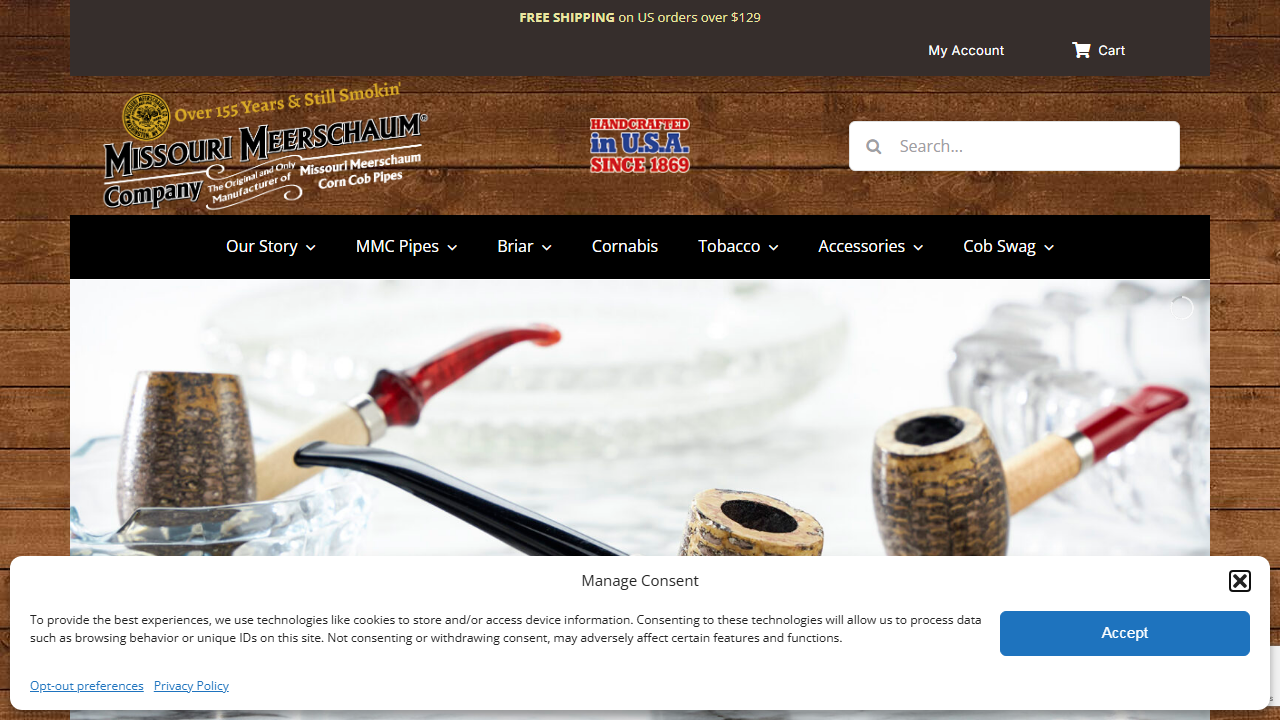

Missouri Meerschaum

"World's oldest and largest corn cob pipe manufacturer since 1869."

A Living Tradition

In 1869, Henry Tibbe walked into his Washington, Missouri workshop with an unusual request: could he make a pipe from corn cobs? As a woodturner, he was used to working with hardwoods, but a customer insisted that corn cobs, when properly prepared, made excellent smoking pipes.

Tibbe was skeptical, but he tried it—and discovered something remarkable: corn cobs smoked cooler, didn't ghost flavors, and were remarkably durable.

He founded Missouri Meerschaum, named after the German word for sea foam—the material's white color reminded German immigrants of the foam on ocean waves.

When customers asked for his secret, Tibbe shared it freely, believing that good craftsmanship should benefit everyone.

Today, Missouri Meerschaum remains in the Tibbe family, producing the same pipes that graced the workshops of Mark Twain and the camps of cowboys heading West.

It's a story of innovation, family tradition, and the understanding that sometimes the simplest solutions are the best.

The Art of Handcrafted Excellence

Creating pipes from corn cobs might sound simple, but it requires a process that's been refined over 150 years.

It begins with specially selected corn—grown specifically for pipe making, with cobs that are the right size and density.

The cobs are dried for months in climate-controlled sheds, losing moisture gradually to prevent cracking.

Once properly aged, the cobs are turned on precision lathes, with craftspeople carefully shaping each pipe to specific dimensions while preserving the natural characteristics that make corn cob pipes special.

The bowls are then treated with a carbonizing process that creates a smooth, heat-resistant surface that can withstand the heat of burning tobacco.

Stems are made from hardwood or vulcanite, with mouthpieces shaped for comfort.

Assembly involves fitting the stem to the bowl with precision, ensuring a perfect smoke.

Each pipe is inspected for flaws, tested for fit, and packaged with the understanding that it's not just a pipe—it's a connection to American history.

It's manufacturing where handcraftsmanship meets timeless design.

Bass Pro Shops

"Premier outdoor retailer and manufacturer of fishing and hunting gear."

The Founder's Vision

In 1972, Johnny Morris was a young fishing guide in the Ozarks, frustrated by the lack of quality fishing equipment available.

So he started making his own tackle—poppers that caught fish and plugs that looked real enough to fool even smart bass.

His friends noticed, then their friends noticed, and soon Morris was running a mail-order business from his garage.

When those orders grew into something bigger, Morris opened a small shop in Springfield, filling it with the outdoor gear he believed in: quality products that actually worked when you needed them most.

He built relationships with manufacturers, insisting on products that met his standards.

He created an experience—stores that felt like being in the wilderness without leaving civilization.

Today, Bass Pro Shops is the world's leading outdoor retailer, but Johnny Morris never forgot his roots: the best gear comes from understanding what outdoorsmen actually need.

It's a company built by an outdoorsman, for outdoorsmen, with the understanding that your gear can make or break your time in nature.

The Art of Handcrafted Excellence

Creating outdoor gear worthy of the Bass Pro Shops name requires understanding that your product might be the difference between success and failure in the wilderness.

Bass Pro Shops works directly with manufacturers to design products that meet real-world conditions: rods that can handle trophy fish, reels that won't fail during the fight of a lifetime, boots that won't quit when you're 20 miles from the truck.

Quality control begins with design—prototypes are tested extensively by professional guides, tournament anglers, and serious hunters who push gear to its limits.

Materials are selected for durability: rod guides that resist corrosion, reel components machined from premium metals, fabrics that resist tears and abrasion.

Manufacturing is closely monitored, with Bass Pro Shops representatives visiting factories to ensure standards are maintained.

Before products reach shelves, they undergo rigorous testing: saltwater exposure testing for corrosion resistance, impact testing for durability, and real-world testing in the conditions the gear is designed for.

It's manufacturing where performance isn't just a goal—it's a promise.