Cornhusker Craftsmanship

"From Omaha's steak houses to Lincoln's manufacturing plants—discover the brands powering America's heartland."

Where American Values Drive Innovation

Nebraska has always been a place where hard work pays off and old-fashioned values meet modern innovation. In the fields surrounding small towns, family farmers work the same land their great-grandparents planted, supplying the corn and soybeans that feed America. In the cities, manufacturers build everything from precision medical devices to outdoor gear that's trusted worldwide. This is the Cornhusker State, where they don't just talk about quality—they live it. Whether it's Becton Dickinson's life-saving medical equipment, Cabela's gear that outfits hunters and anglers, or Lindsay Corporation's irrigation systems that water crops from Nebraska to Africa, Nebraska companies understand that what they make matters. It's a state where a handshake is still a contract, and where pride in craftsmanship runs as deep as the Platte River.

Becton Dickinson

"Global medical technology company producing life-saving syringes and devices."

The Story Behind the Brand

BD's Holdrege facility represents the company's commitment to manufacturing medical devices that save lives every day.

From this Nebraska plant, BD produces millions of syringes, needles, and other medical devices that are used in hospitals and clinics worldwide.

The facility employs hundreds of skilled technicians and engineers who understand that their work directly impacts patient care.

BD's Nebraska operations exemplify how medical technology companies combine precision engineering with strict quality control.

Every syringe manufactured in Holdrege meets the highest standards for sterility and performance, ensuring that healthcare providers can trust these critical devices.

The plant's location in rural Nebraska allows BD to draw on a workforce known for its work ethic and attention to detail.

A Commitment to Quality

Manufacturing medical devices requires precision and care at every step.

BD's production lines use advanced robotics and automation to ensure consistent quality, but human oversight remains critical.

Syringes are formed from medical-grade plastic that's molded at high temperatures, creating components that fit together with microscopic precision.

Every batch of raw materials is tested before it enters production.

The molding process happens in clean rooms where air quality is strictly controlled.

After molding, components are assembled automatically, with vision systems checking for defects that the human eye might miss.

Finally, devices are sterilized using gamma radiation or ethylene oxide, then packaged in sterile barriers.

Quality testing continues throughout the process.

Cabela's

"Outdoor gear retailer and manufacturer serving hunters, anglers, and outdoor enthusiasts."

The Founder's Vision

Richard Cabela started Cabela's in 1961, selling hunting gear from the basement of his Sidney, Nebraska home.

What began as a small business serving local hunters has grown into one of America's most trusted outdoor brands.

Cabela's built its reputation on quality gear that can withstand the toughest conditions, from Arctic expeditions to African safaris.

The company's Sidney headquarters remains a monument to the outdoor lifestyle, featuring a massive store that's also a museum of hunting and fishing heritage.

Cabela's understands that outdoor gear isn't just equipment—it's the difference between success and failure in the wilderness.

Their products are tested by professionals who rely on them in the world's most challenging environments.

A Commitment to Quality

Cabela's product development starts with input from professional guides, hunters, and anglers who understand what gear needs to do in extreme conditions.

Designers create prototypes that are tested extensively in real-world situations.

Manufacturing partners are selected not just for cost, but for their ability to meet Cabela's exacting standards.

Every product category has specific testing protocols: sleeping bags are tested in climate-controlled chambers, boots undergo thousands of flex cycles, and outerwear is exposed to simulated rain and wind.

The company's quality control team inspects products at multiple stages, ensuring that only gear meeting Cabela's standards reaches customers.

The result is outdoor gear that outdoor enthusiasts trust with their lives.

TradeNet

"Industrial supplier connecting manufacturers with quality components."

The Story Behind the Brand

TradeNet has been Nebraska's bridge between manufacturers and the components they need to build quality products.

Based in Omaha, the company understands that American manufacturing depends on a network of reliable suppliers who can deliver exactly what's needed, when it's needed.

TradeNet's expertise spans multiple industries, from automotive to agriculture, helping companies source everything from precision fasteners to custom-fabricated components.

The company's deep understanding of manufacturing processes allows them to advise clients on the best materials and specifications for their applications.

TradeNet represents the kind of American business intelligence that keeps manufacturing competitive: knowing the right supplier, at the right price, with the right quality, delivered on time.

A Commitment to Quality

TradeNet's sourcing process begins with understanding each client's exact requirements: specifications, quality standards, delivery schedules, and budget constraints.

The company's team maintains relationships with hundreds of suppliers across North America, matching client needs with supplier capabilities.

Every potential supplier is vetted for quality systems, capacity, and reliability.

TradeNet manages the entire procurement process, from quote comparison to delivery coordination, allowing clients to focus on their core manufacturing activities.

The company uses technology platforms to track orders, manage inventory, and provide clients with real-time visibility into their supply chains.

When issues arise, TradeNet's team works to resolve them quickly.

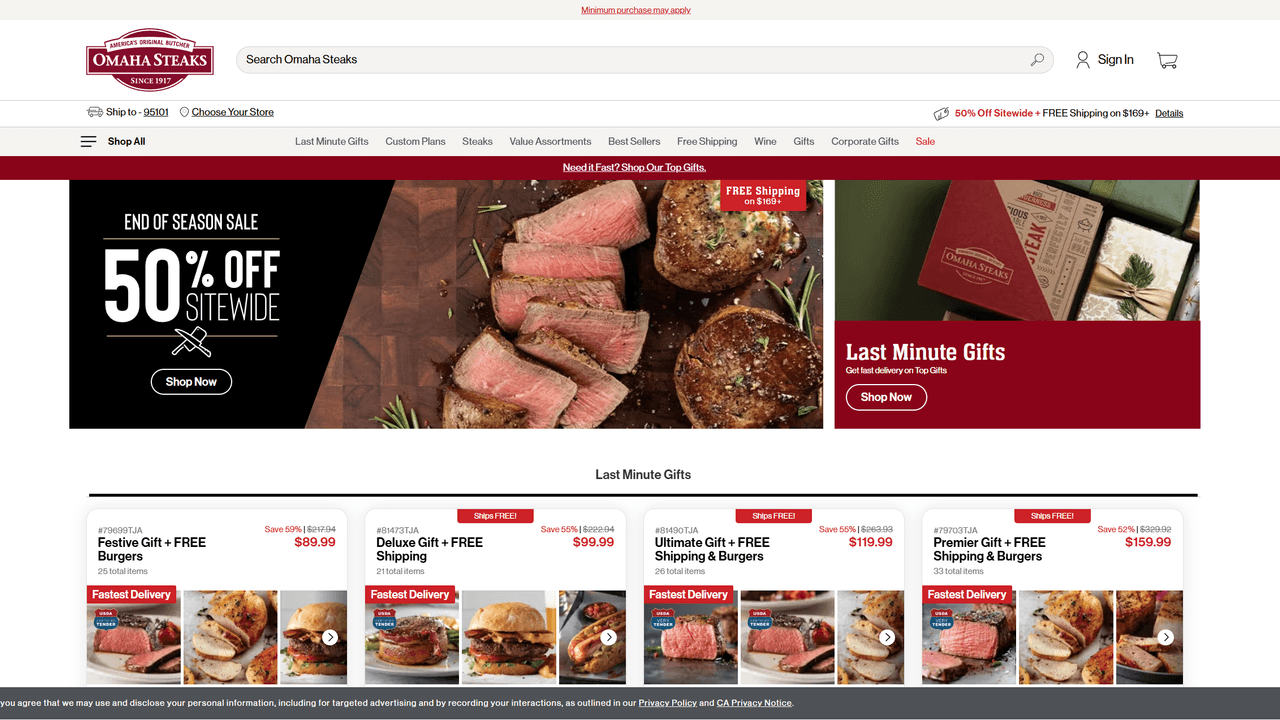

Omaha Steaks

"Premium steaks and gourmet foods delivered nationwide from Nebraska."

The Founder's Vision

Omaha Steaks began in 1917 when a Russian immigrant named B.J.

From started selling beef from a horse-drawn cart in downtown Omaha.

The company has grown from that simple beginning into one of America's most trusted sources for premium steaks and gourmet foods.

What sets Omaha Steaks apart is their commitment to quality at every step, from selecting the finest cattle to packaging products that arrive at customers' doors in perfect condition.

The company's Omaha headquarters and production facilities employ thousands of Nebraskans who take pride in delivering the world's best steaks.

Omaha Steaks represents the heart of American beef culture: quality, tradition, and a commitment to excellence that never wavers.

The Art of Handcrafted Excellence

Omaha Steaks' process begins with carefully selected cattle, sourced from trusted ranchers who follow strict standards for breed, feed, and animal welfare.

The beef is dry-aged for enhanced flavor and tenderness, then cut by skilled butchers who understand how to maximize quality and value.

Each steak is trimmed by hand, ensuring that only the finest cuts reach customers.

Packaging uses advanced freezing technology to lock in freshness and flavor, allowing steaks to be shipped nationwide without compromising quality.

Omaha Steaks operates a vertically integrated supply chain, controlling every step from ranch to table.

Every product is inspected multiple times to ensure it meets the company's exacting standards.

Lozier

"Retail fixture manufacturer creating innovative store displays and environments."

The Story Behind the Brand

Lozier has been designing and building retail fixtures for over 130 years, helping stores across America create displays that attract customers and drive sales.

Based in Omaha, the company understands that retail is an art form where every detail matters: the height of a shelf, the spacing of a display, the materials used in construction.

Lozier's fixtures are found in retailers from small boutiques to massive big-box stores, always designed to showcase products in their best light.

The company's commitment to American manufacturing means their fixtures are built to last, using materials and construction techniques that can withstand years of use.

Lozier represents the intersection of form and function, where practical manufacturing meets retail artistry.

The Art of Handcrafted Excellence

Lozier's design process begins with understanding the client's brand, products, and merchandising strategy.

Designers create detailed drawings and 3D models, showing how fixtures will look and function in the retail environment.

Manufacturing uses precision equipment to cut and form metal components, ensuring every piece fits together perfectly.

Welding, assembly, and finishing happen in Lozier's Omaha facility, where skilled craftspeople bring designs to life.

Quality control happens at every step, from material inspection to final product testing.

Lozier's installation teams work with retailers to ensure fixtures are installed correctly and integrated seamlessly into their stores.

Lindsay Corporation

"Irrigation and infrastructure solutions feeding the world."

Innovation Born from Necessity

Lindsay Corporation has been helping farmers water their crops efficiently for over 60 years, turning the semiarid plains of Nebraska into some of the most productive farmland in the world.

The company's innovative irrigation systems are used on farms from Nebraska to New Zealand, helping grow the food that feeds billions.

Lindsay's pivot irrigation systems move water across fields with precision, delivering exactly the right amount to each plant.

The company has also pioneered road infrastructure products, from safety barriers to sign supports that line America's highways.

Based in Omaha, Lindsay represents Nebraska's commitment to innovation that makes a real difference in the world.

Their products literally help feed the planet.

How It's Made

Manufacturing irrigation equipment requires robust engineering and construction.

Lindsay's pivots are built from galvanized steel that can withstand decades of outdoor exposure.

Components are manufactured using CNC machining and robotic welding for precision and durability.

Each pivot is custom-configured for specific field conditions: soil type, crops, topography, and water availability.

The company's proprietary control systems use GPS and sensors to optimize water application, reducing waste and increasing yields.

Every product is tested extensively before shipping, including structural testing, electronics validation, and field trials.

Lindsay's engineering team continues to innovate, developing systems that use less water and energy while improving crop production.