Rugged Mountain Craftsmanship

"In the Wasatch Range and Great Basin, makers create goods as enduring as the landscape."

Innovation Meets Tradition

Utah's manufacturing tradition is forged in the mountains and refined in the desert. From the mining heritage of the west to the tech innovation of Salt Lake City, from the agricultural valleys to the red rock canyons, Utah's makers understand that persistence pays off. The brands featured here represent the diversity of Utah's manufacturing: ancient salt from Jurassic seas, transparent skateboards using cutting-edge materials, ceiling-mounted drying racks for efficient living, bean-to-bar chocolate crafted with precision, plush blankets sewn by local artisans, and kitchen tools that honor home baking traditions. Each product carries Utah's spirit: practical innovation, respect for resources, and the belief that quality never goes out of style.

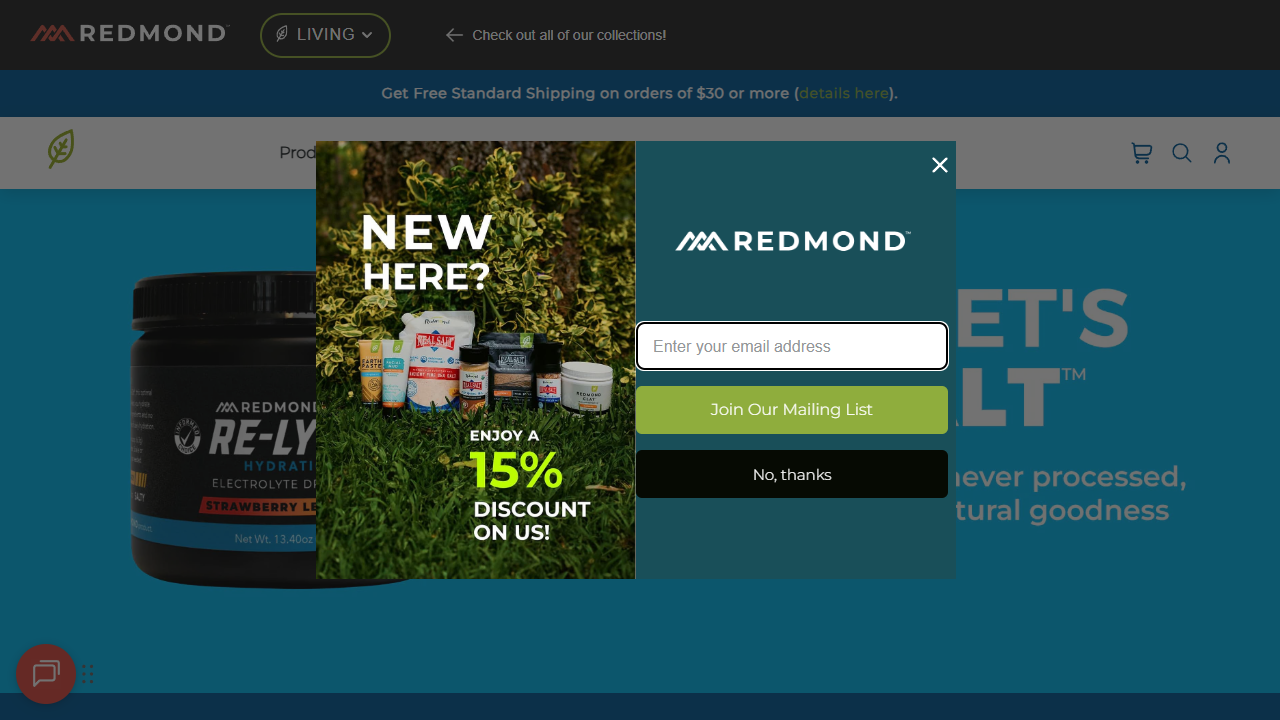

Redmond Real Salt

"Unrefined mineral salt harvested from an ancient underground deposit."

Innovation Born from Necessity

Redmond Real Salt is not manufactured in a factory; it is harvested from the Jurassic period.

The source is an ancient inland sea (the Sundance Sea) that trapped salt deposits under a layer of volcanic ash and bentonite clay millions of years ago.

This geological cap protected the salt from modern pollutants, a key marketing claim that distinguishes it from sea salts harvested from current oceans.

Unlike solar salt, which is produced by evaporating brine in ponds, Redmond salt is dry-mined.

The company uses stainless steel hydraulic rotary tools to grind the salt directly from the mine walls, 370 feet underground.

Explosives are strictly prohibited to prevent contamination.

The salt is brought to the surface, crushed, and screened for size.

Critically, it is unrefined.

It is not bleached or treated with anti-caking agents.

The resulting product contains over 60 natural trace minerals, giving it a distinctive pink hue and a unique flavor profile.

A Commitment to Quality

The salt harvesting process at Redmond begins with careful geological surveying to locate the purest sections of the ancient deposit.

Mining operations use continuous mining machines that grind the salt from the mine face using rotating bits.

The salt is then transported to the surface via conveyor systems, where it undergoes primary crushing and screening to separate particles by size.

No chemical processing or refining is performed—the salt is simply cleaned to remove rock and debris.

The product is packaged in its natural state, with trace minerals intact.

Quality control includes regular testing for purity and mineral content.

The packaging process is designed to preserve freshness and prevent contamination, with many products sold in resealable containers.

The entire operation emphasizes sustainability, with the mine operating as a closed system that minimizes environmental impact while providing a pure, unprocessed product that connects consumers to ancient geological processes.

Ghost Boards

"Transparent acrylic skateboards and longboards with LED integration."

A Living Tradition

Ghost Boards illustrates how material science can disrupt established industries.

The skateboard industry has traditionally relied on Canadian maple laminate.

Ghost Boards introduced a proprietary acrylic formulation that is transparent, allowing for a completely different visual aesthetic.

The manufacturing process involves cutting and shaping these acrylic sheets into varying deck profiles (pintail, drop-down).

The acrylic offers a unique flex pattern that absorbs road vibration differently than wood.

The transparency also allows for the integration of LED lighting systems directly into the hardware, turning the board into a light source.

By keeping production in Utah, Ghost Boards maintains strict quality control over the clarity and structural integrity of the acrylic, preventing the yellowing or brittleness often seen in cheaper imported plastics.

This innovation has created a new category in the skateboard market, combining functionality with visual artistry.

A Commitment to Quality

The manufacturing process at Ghost Boards begins with formulating their proprietary acrylic blend, a closely guarded secret that provides the perfect balance of flexibility and durability.

The acrylic sheets are precision-cut using CNC routers programmed with exact specifications for each deck shape.

Cutting requires careful attention to material thickness and edge finish to ensure safety and performance.

The shaping process involves sanding edges smooth and creating mounting holes for trucks and hardware.

Some boards feature integrated LED systems, which are installed during assembly with wiring protected within the deck structure.

Quality control includes stress testing each board to ensure it meets safety standards for skateboarding.

The final step involves applying protective coatings that enhance UV resistance and scratch protection.

Each board is inspected for clarity, structural integrity, and aesthetic quality before being carefully packaged with protective materials.

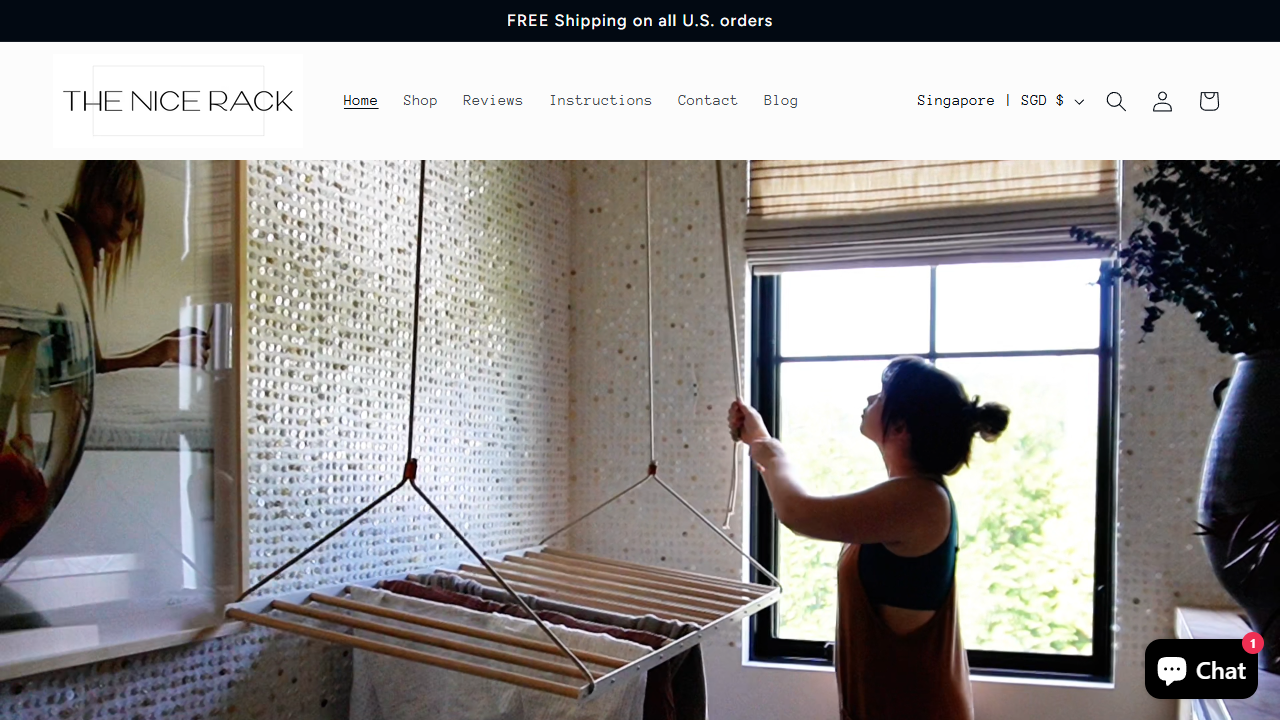

The Nice Rack

"Ceiling-mounted drying racks for sustainable laundry drying."

A Living Tradition

The Nice Rack is a Utah-based manufacturer of ceiling-mounted laundry drying racks.

Founded by Holli Harris in Salt Lake City, the company adapted the traditional European drying rack design for the American market.

The racks are constructed from powder-coated metal and water-resistant hardwood dowels.

The system uses a pulley mechanism to hoist laundry to the ceiling, utilizing rising heat to dry clothes efficiently and sustainably.

The manufacturing involves local metal fabrication and woodworking to ensure the product can safely bear up to 50 lbs of wet laundry.

This innovative solution addresses the growing concern about energy consumption in home appliances while providing a practical alternative to traditional dryers.

The Nice Rack embodies the Utah ethos of practical innovation—simple solutions that make everyday life more efficient and environmentally friendly.

A Commitment to Quality

The manufacturing process at The Nice Rack begins with selecting powder-coated steel tubing and hardwood dowels, chosen for their durability and aesthetic appeal.

The metal components are cut to precise lengths using industrial saws, then welded together to form the rack's frame.

Welding is performed by skilled technicians who ensure strong, clean joints that can support heavy loads.

After welding, frames receive a powder coating finish that provides durability and a smooth surface.

The powder coating process involves applying electrostatically charged powder to the metal, then curing it in high-heat ovens to create a hard, protective surface.

Wood components are turned on lathes to create smooth, consistent dowels that fit precisely into the metal framework.

The rope and pulley system is assembled using heavy-duty components rated for the weight capacity.

Each complete rack is tested to ensure it operates smoothly and can support the rated load before being carefully packaged with installation instructions.

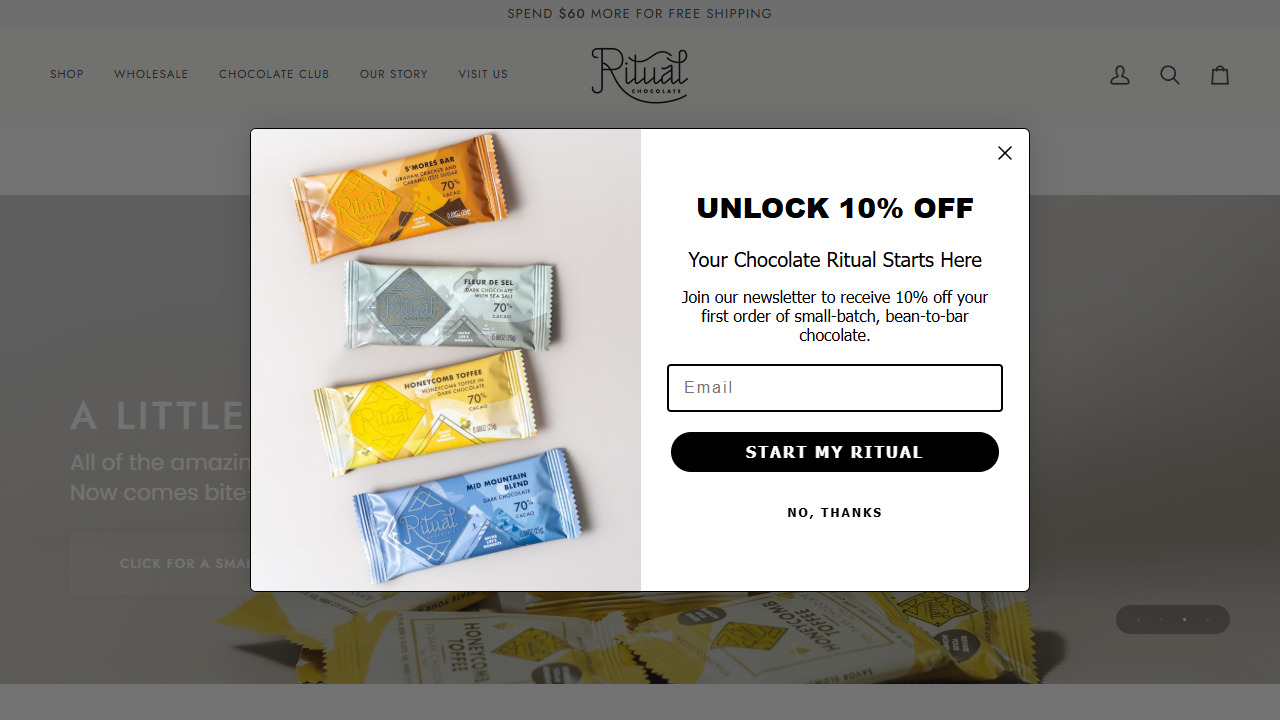

Ritual Chocolate

"Bean-to-bar craft chocolate highlighting single-origin terroir."

Innovation Born from Necessity

Ritual Chocolate represents the high-tech side of food manufacturing.

Operating out of Heber City, the company controls every step of the chocolate-making process.

It begins with sourcing fermented cacao beans, which are roasted to develop flavor precursors.

The company practices a 'bean-to-bar' philosophy, controlling every step of production to highlight the unique terroir of different cacao origins.

In their Utah factory, they roast, winnow, and grind the beans using stone melangeurs.

The chocolate is refined and conched for days to develop flavor and texture before being tempered and molded.

This slow manufacturing process preserves the nuanced fruit and spice notes of the cacao, contrasting with industrial chocolate production.

The brand has become a destination for chocolate enthusiasts who appreciate the subtle differences that origin, processing, and craftsmanship can create in the final product.

The Art of Handcrafted Excellence

The chocolate-making process at Ritual begins with carefully selecting cacao beans from specific origins, each chosen for their unique flavor potential.

The beans are roasted in small batches using precise temperature profiles developed through extensive testing.

Roasting brings out flavor compounds while preserving the bean's inherent characteristics.

After roasting, the shells are removed through winnowing, leaving cacao nibs that are ground into a paste called 'chocolate liquor.' The grinding process uses stone melangeurs that grind the nibs and sugar together to a particle size of 15-20 microns, ensuring a smooth texture.

The mixture is then conched—aerated and heated/cooled—for days to drive off volatile acids and develop the final flavor profile.

Finally, the chocolate is 'tempered,' a thermodynamic process of heating and cooling that aligns the cocoa butter crystals to ensure the bar has a glossy finish and a sharp snap.

Each bar is molded, cooled, and wrapped by hand, reflecting the artisanal nature of the process.

Minky Couture

"High-quality plush blankets with extensive customization options."

Innovation Born from Necessity

Minky Couture has scaled a home-sewing business into a manufacturing giant.

The company produces plush blankets using 'Minky' fabric (a microfiber polyester).

What makes their manufacturing unique is their reliance on local seamstresses.

While they have central warehouse operations for cutting and shipping, much of the sewing has historically been done by a network of local contract sewers.

This model allows for immense flexibility and customization, enabling the brand to offer hundreds of fabric combinations.

The company has reached the milestone of selling over one million blankets.

Their 'Heart of Minky' program donates mini blankets to NICUs, integrating philanthropy into the production cycle.

The brand exemplifies the Utah entrepreneurial spirit—starting small, growing through quality and community support, and maintaining values that prioritize both business success and social good.

A Commitment to Quality

The blanket manufacturing process at Minky Couture begins with selecting high-quality Minky fabric in hundreds of patterns and colors.

The fabric is cut to size using industrial cutting machines that ensure precision and minimize waste.

Cutting operations are centralized in their facilities, where patterns are optimized to maximize fabric utilization.

The sewing process is distributed among a network of skilled local seamstresses who work from home or small shops.

Each seamstress receives pre-cut fabric pieces and detailed instructions for assembly.

The sewing process involves precise stitching that creates durable, comfortable blankets with mitered corners and reinforced seams.

Quality control is maintained through regular inspections and feedback loops with the sewing network.

After sewing, blankets return to the central facility for final inspection, folding, and packaging.

The company emphasizes ethical labor practices and fair compensation for their sewing contractors, creating economic opportunities within the local community while maintaining production flexibility.

The Food Nanny

"Kitchen tools and baking solutions focused on family traditions."

A Living Tradition

The Food Nanny represents the intersection of culinary tradition and modern convenience.

The brand, led by Lizi and Annie, focuses on the resurgence of home baking, recognizing that many families want to return to the practice of making bread and other baked goods together.

Their flagship manufactured product is a stainless steel Dough Hook designed to withstand the torque of mixing heavy bread dough.

Unlike standard whisks, this tool is engineered for specific baking challenges.

The brand partners with NuQuest, a Salt Lake City manufacturer, to produce these tools.

The hook is made from heavy-gauge stainless steel rod, bent to a specific curvature that optimizes mixing efficiency.

The handle is turned wood.

This partnership exemplifies the 'Silicon Slopes' effect, where digital brands leverage local industrial capacity to create physical products that support their mission of bringing families together through cooking.

The Art of Handcrafted Excellence

The manufacturing process for The Food Nanny's dough hook begins with selecting heavy-gauge stainless steel rod that can withstand the pressure of mixing dense bread dough.

The steel is bent to precise specifications using hydraulic benders that create consistent curves every time.

The bending process requires skill to achieve the optimal angle and radius for efficient dough mixing.

After bending, the hook end is machined to create a smooth surface that won't snag dough or damage bowls.

The handle is turned from hardwood on precision lathes, with attention to ergonomic shape and comfortable grip.

The stainless steel and wood components are joined using high-strength adhesives designed for food-contact applications.

Each completed tool is inspected for proper assembly, smooth surfaces, and structural integrity.

The final product is packaged with instructions and recipes, emphasizing the brand's focus on family baking traditions.

Quality testing includes actual bread-making to ensure the tool performs as advertised.