Green Mountain Craftsmanship

"From Quechee's glass kilns to Shelburne's teddy bear workshop—explore six brands carrying forward Vermont's commitment to quality and tradition."

Where Heritage Meets Heart

In Vermont's green mountains, craftsmanship isn't just a business—it's a way of life. For over a century, makers in this small state have been proving that quality doesn't require scale, and that tradition thrives when infused with innovation. From the glassblowers at Simon Pearce who've transformed molten sand into art for daily meals, to the sock knitters at Darn Tough who back their work with an unconditional lifetime guarantee, Vermont brands share a common thread: they make things meant to last. These six stories represent the best of Vermont's manufacturing heritage—brands that have survived by never compromising on quality, always investing in their workers, and finding ways to turn local resources into treasures that grace homes across America.

Vermont Glove

"Heavy-duty, handcrafted goat leather work gloves powered by 100% renewable energy."

A Living Tradition

Vermont Glove embodies the resilience and practicality of the Green Mountain State.

With roots dating back to 1920 when it was founded as the Green Mountain Glove Company, the business has been protecting the hands of line workers, farmers, and laborers for over a century.

In 2018, the company was revitalized by Sam Hooper, a young entrepreneur who purchased the business to ensure the survival of this local manufacturing gem.

Under Hooper's leadership, the company moved into a converted creamery in Randolph, Vermont, and transitioned to running on 100% renewable solar energy, marrying traditional craftsmanship with modern environmental responsibility.

Each glove is meticulously handcrafted from goat leather, a material chosen for its superior properties—tighter fiber structure, higher strength-to-weight ratio, and the unique ability to remain soft even after getting wet and drying out.

The Art of Handcrafted Excellence

The manufacturing process at Vermont Glove is meticulous and labor-intensive, involving skilled sewers who use vintage Singer machines to double-stitch gloves with heavy-duty nylon thread.

The patterns are engineered to place seams away from high-wear areas, significantly extending the life of each glove.

Each glove consists of roughly 12 separate pieces of leather, carefully assembled to ensure dexterity and fit.

The goat leather is first cut using patterns designed for maximum durability, then the pieces are sewn together with reinforced stress points.

What sets Vermont Glove apart is their commitment to renewable energy—the entire facility runs on solar power, and they've even added a wind turbine.

The result is a work glove that not only protects your hands but represents a commitment to sustainable American manufacturing.

Darn Tough Vermont

"Performance Merino wool socks backed by an Unconditional Lifetime Guarantee."

A Family Legacy

Darn Tough Vermont is a legendary name in the outdoor industry, synonymous with durability and quality.

The brand is the house label of Cabot Hosiery Mills, a family-owned manufacturer in Northfield, Vermont, that has been knitting socks since 1978.

Founded by Marc Cabot, the mill faced a crisis in the early 2000s as the American textile industry collapsed due to overseas outsourcing.

Marc's son, Ric Cabot, launched the Darn Tough brand in 2004 with a radical promise to save the family business: an Unconditional Lifetime Guarantee.

If a customer can wear out a pair of Darn Tough socks, the company will replace them for free, no questions asked.

This guarantee forced the company to manufacture the most durable sock possible, creating a cult following among hikers, runners, and tradespeople who rely on their feet for their livelihood.

Innovation Meets Craftsmanship

Darn Tough socks are made in Northfield using 100% RWS-certified Merino wool, a material prized for its natural moisture-wicking, antimicrobial, and thermoregulating properties.

The manufacturing process utilizes fine-gauge knitting machines with an incredibly high stitch count, creating a dense, protective fabric that doesn't slip, bunch, or cause blisters.

A key innovation is their 'True Seamless' toe technology, which eliminates the bulky seam across the toes that is a common source of irritation.

Each sock is knit with dense loops throughout the cushion zones, with additional reinforcement in the heel and toe boxes where wear is highest.

The result is a sock so durable that the company can confidently offer their unconditional lifetime guarantee, knowing that very few will ever need to use it.

Simon Pearce

"Hand-blown lead-free glass stemware and handmade pottery designed for daily use."

The Story Behind the Brand

Simon Pearce is a prestigious name in American design, renowned for its exquisite hand-blown glass and handmade pottery.

The company was founded by Simon Pearce, an Irish-born artisan who apprenticed in the great glass houses of Europe before moving to the United States in 1981.

Seeking a location that could provide sustainable energy for his glass furnaces, he restored an historic 19th-century woolen mill on the Ottauquechee River in Quechee, Vermont, converting it to run on hydroelectric power.

This mill remains the heart of the brand, serving as a manufacturing facility, showroom, and renowned farm-to-table restaurant.

Today, Simon Pearce bridges the gap between rustic Vermont charm and modern elegance, creating functional art that elevates everyday moments.

The Art of Handcrafted Excellence

The manufacturing process at Simon Pearce is a celebration of traditional craftsmanship.

Visitors to the mill can watch teams of master glassblowers gather molten glass from the furnaces and shape it using centuries-old techniques and wooden molds.

The glass itself is formulated to be lead-free and exceptionally clear, designed with a philosophy of 'functional sophistication'—beautiful enough for special occasions but durable enough for everyday use.

Each piece goes through multiple stages: gathering the molten glass, shaping it with tools and molds, cooling it slowly in a 'annealing' kiln to relieve internal stresses, and finishing with polishing.

The pottery is similarly handcrafted, hand-thrown, and finished with earthy, resilient glazes.

Despite its growth into a nationally recognized luxury brand, Simon Pearce remains committed to its artisan roots, ensuring that the human hand is evident in every piece.

The Vermont Flannel Company

"Heavyweight, double-brushed organic cotton flannel shirts and loungewear."

The Story Behind the Brand

The Vermont Flannel Company has been keeping people warm and cozy since 1991, establishing itself as an authority on authentic, high-quality flannel.

Founded by Mark and Linda Baker in East Barre, Vermont, the company was born from a desire to create a flannel that was superior to the thin, mass-produced options flooding the market.

Mark Baker is even credited with inventing 'flannel lounge pants,' a product category that has since become a global staple of comfort.

The secret to their flannel's legendary softness and durability lies in their commitment to using 100% GOTS-certified organic cotton, yarn-dyed for vibrant, colorfast plaids.

Every garment is hand-cut and sewn in Vermont, supporting local jobs and ensuring the highest quality construction.

The Art of Handcrafted Excellence

The journey of Vermont Flannel begins with carefully sourced 100% GOTS-certified organic cotton, which is yarn-dyed rather than printed, ensuring that the vibrant plaids remain colorfast wash after wash.

The fabric is tightly woven to minimize shrinkage and then undergoes a unique double-brushing process on both sides—a technique the company describes as 'brushed beyond reason.' This results in a thick, ultra-soft textile that provides exceptional warmth without being scratchy.

The garments are then hand-cut and sewn at their Vermont facilities, with matched stripes and reinforced seams ensuring that each piece meets their exacting standards.

The company operates with a zero-waste philosophy, using every bit of fabric and repurposing scraps.

The result is flannel that embodies the 'hygge' of a New England winter.

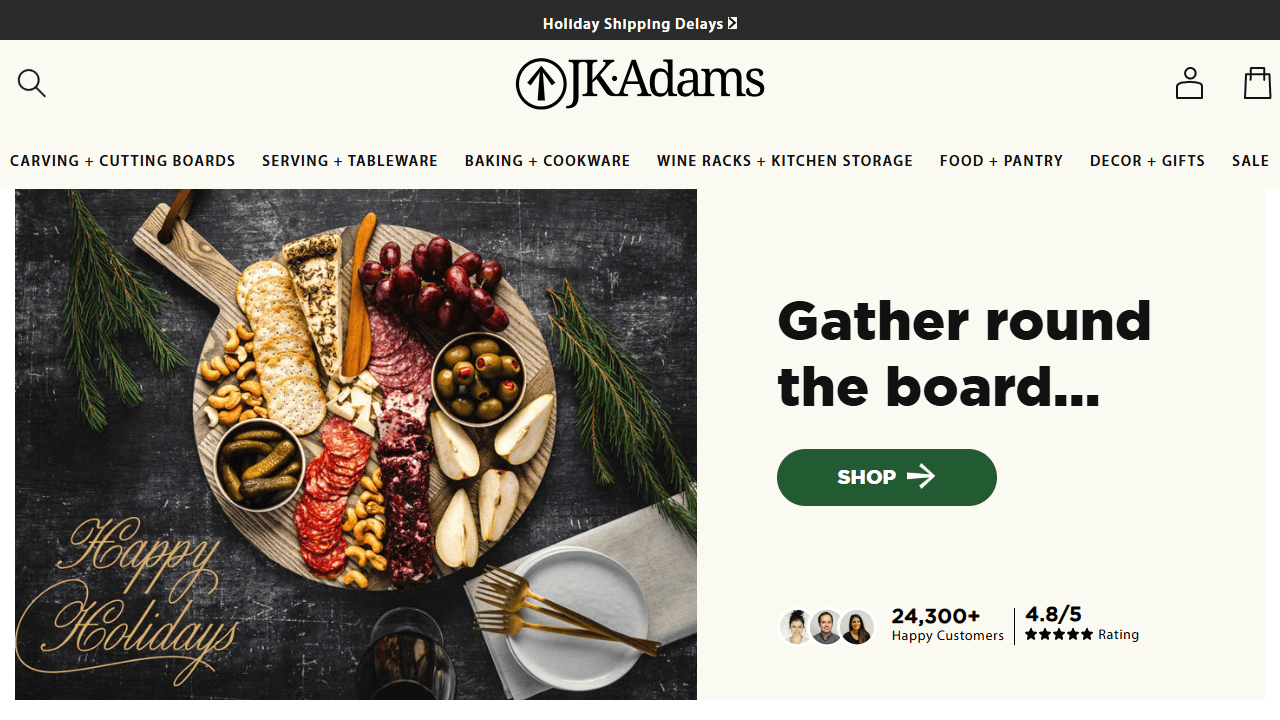

JK Adams

"Handcrafted North American hardwood cutting boards and kitchen tools."

Innovation Born from Necessity

JK Adams is a cornerstone of the American kitchenware industry, producing high-quality wood products in Dorset, Vermont, for over 75 years.

The company was founded in 1944 by Josiah Knowles Adams in a garage, initially making speedy racer toys, before being purchased by the Cooper family in 1949.

Today, it is a second-generation family-owned business led by Malcolm Cooper Jr.

JK Adams is renowned for its innovation in kitchen storage and preparation; they were the first company to introduce the slanted knife block, the spinning spice rack, and the modular wine rack to the American market.

Their manufacturing facility in Dorset is a testament to sustainable production, operating with a zero-waste philosophy where sawdust and scrap wood are collected and burned to heat the entire facility and kiln-dry lumber.

The Art of Handcrafted Excellence

JK Adams sources their lumber—Rock Maple, Cherry, and Black Walnut—exclusively from responsibly harvested North American forests.

The production process combines the precision of modern CNC machinery with the artistry of hand-sanding and oiling.

Boards are cut to size, edge-grain pieces are selected for durability, and the boards are then shaped and smoothed.

Each board undergoes a multi-stage sanding process, starting with coarse grit and progressing to fine grit for a silky-smooth finish.

The final step is hand-oiling with food-safe mineral oil, which penetrates the wood to protect it from moisture and daily use.

The zero-waste facility burns all sawdust and scrap wood in a specialized furnace, significantly reducing their carbon footprint.

Every JK Adams product is backed by an uncompromising lifetime guarantee.

Vermont Teddy Bear

"Customizable, handcrafted teddy bears delivered via signature 'Bear-Gram'."

Innovation Born from Necessity

The Vermont Teddy Bear Company is an American icon, famous for inventing the 'Bear-Gram' concept—a creative alternative to flower delivery where a personalized teddy bear arrives in a colorful box with air holes.

The company was founded in 1981 by John Sortino, who began selling his handmade bears from a cart on Church Street in Burlington, Vermont.

Today, the company operates out of a large facility in Shelburne, Vermont, which serves as a factory, retail store, and tourist destination.

While the company has grown to become one of the largest producers of teddy bears in the U.S., it maintains a dedicated 'Made in USA' collection where bears are stuffed, sewn, and finished by hand.

Each bear represents a lifetime of cuddles and comfort, backed by a unique Lifetime Guarantee.

The Art of Handcrafted Excellence

The manufacturing process at Vermont Teddy Bear is labor-intensive and focused on quality.

Each bear begins as premium mohair or plush fabric, cut according to precise patterns.

Skilled artisans then sew the pieces together using industrial sewing machines, creating the bear's distinctive shape.

The bears are filled using a specialized 'stuffing machine' that ensures perfect huggability—neither too firm nor too soft.

Facial features are added by hand, including the distinctive 'Born in Vermont' eyes that have become a brand trademark.

Each bear can be dressed in hundreds of different outfits representing professions, hobbies, and holidays.

What makes Vermont Teddy Bear special is their 'Bear Hospital'—if a bear is ever damaged, it can be sent back for free repairs.

This commitment to lifetime service makes each bear a keepsake meant to last for generations.