Where American History Lives

"From Colonial craftsmanship to modern innovation, Virginia makers honor tradition while building for the future."

A Legacy of Craftsmanship

Virginia's manufacturing tradition is as old as America itself. From the tobacco farms of the south to the tech corridor of Northern Virginia, from the mountains of the west to the tidewater of the east, Virginia has always been about making things that last. The brands featured here represent the diversity of Virginia's manufacturing: heritage leather goods crafted in Richmond, denim jeans built to age beautifully, coffee roasted in the Blue Ridge Mountains, pottery painted with botanical designs, and outdoor gear tested on Appalachian trails. Each product carries Virginia's DNA: respect for tradition, commitment to quality, and the understanding that what we make should improve with time.

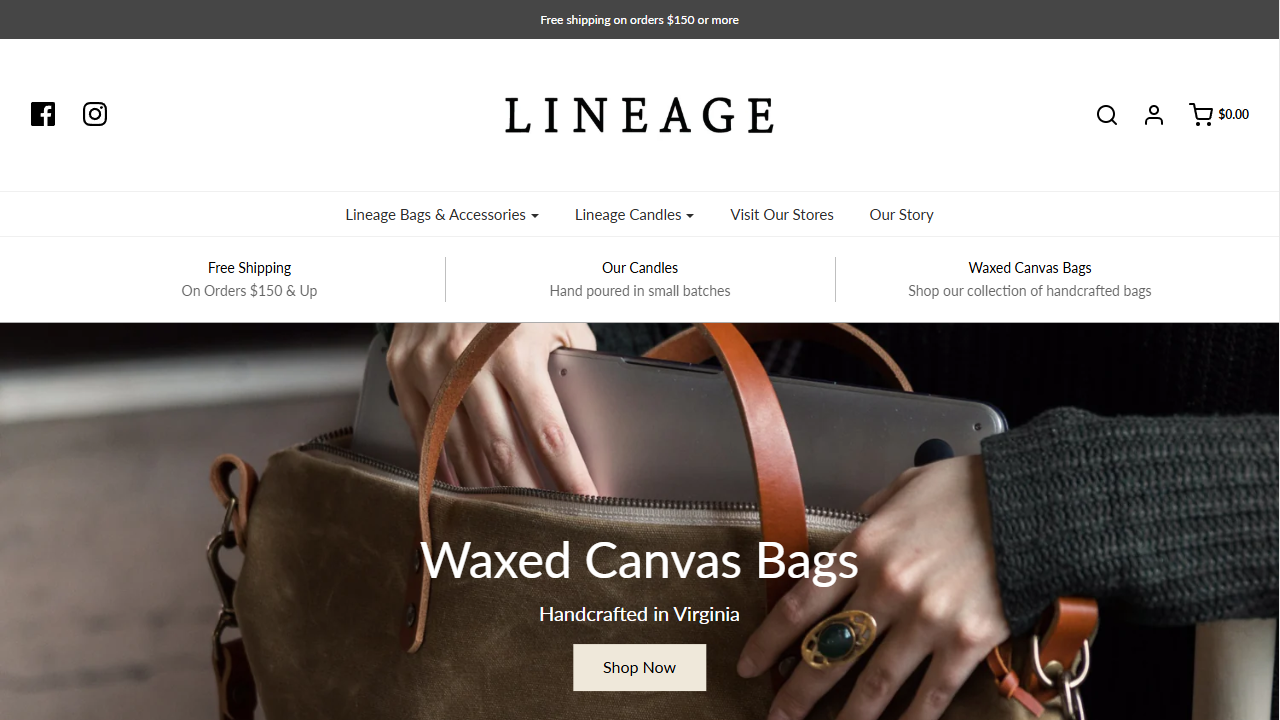

Lineage

"Handcrafted waxed canvas and vegetable-tanned leather bags designed for utility and longevity."

Innovation Born from Necessity

Lineage is a Richmond-based design studio and workshop that exemplifies the modern resurgence of American craftsmanship.

Founded in 2016 by Paul Hansbarger, initially in Harrisonburg, Virginia, the brand was born from a personal need when Paul's pregnant wife, Jessica, requested a functional yet stylish diaper bag.

Paul, leveraging his sewing skills, created a bag that balanced utility with a minimalist aesthetic, sparking demand that grew into a full-fledged business.

Lineage is distinguished by its 'heirloom quality' philosophy; every product is designed to withstand the rigors of daily use and improve with age.

The primary materials used are waxed cotton canvas and full-grain, vegetable-tanned leather, both sourced from American mills and tanneries.

The vegetable tanning process, which uses natural tannins rather than harsh chemicals, allows the leather to develop a rich, unique patina over time, telling the story of the owner's travels.

Manufacturing takes place in their Richmond studio, where bags are cut and sewn by hand in small batches, ensuring ethical labor practices and meticulous quality control.

The Art of Handcrafted Excellence

The bag-making process at Lineage begins with selecting premium materials: waxed canvas from industrial mills and full-grain vegetable-tanned leather that develops character with use.

Each pattern piece is hand-cut, allowing for adjustments and customization that mass production cannot accommodate.

The construction process emphasizes durability through traditional techniques: saddle-stitched seams that hold even if one stitch breaks, solid brass hardware that ages to a warm patina, and reinforced stress points that prevent common failure areas.

The leather is treated with natural oils and waxes that repel water while allowing the material to breathe and develop a rich character over time.

Every bag is assembled by skilled craftspeople who take pride in their work, understanding that they are creating products meant to last decades, not seasons.

The finishing touches include burnishing edges smooth and testing each piece for quality before it leaves the studio.

Shockoe Atelier

"Small-batch, handmade selvedge denim jeans backed by a free lifetime repair guarantee."

A Family Legacy

Shockoe Atelier is a luxury denim manufacturer located in the historic Shockoe Bottom neighborhood of Richmond, Virginia, an area the brand honors by integrating the history of American tobacco and textile commerce into its identity.

Founded in 2012 by Matt Rho and his family, Shockoe Atelier was established to merge the refined tailoring techniques of European fashion houses with the rugged durability of American workwear.

The brand operates with a philosophy of radical transparency; their workshop is integrated directly into their retail showroom, allowing customers to witness the skilled team of artisans—many of whom are immigrants contributing their tailoring expertise—cutting and sewing jeans by hand.

Shockoe Atelier is notable for its 'farm-to-fabric' ambition, having been a primary partner of Vidalia Mills in Louisiana, which famously resurrected the Draper X3 looms from the shuttered White Oak plant to bring selvedge denim production back to the American South.

A key differentiator for the brand is their free lifetime repair guarantee, which covers rips, tears, and blowouts forever.

Time-Honored Techniques

The denim manufacturing process at Shockoe Atelier is a marriage of old-world craftsmanship and modern precision.

It begins with sourcing selvedge denim from American mills, particularly the sought-after denim woven on vintage Draper X3 looms.

Each pair of jeans is cut from premium denim that has been pre-shrunk and Sanforized to ensure consistent fit.

The cutting process uses traditional patterns that have been refined over years of production, with each piece carefully laid out to optimize fabric utilization while minimizing waste.

Sewing is performed on vintage Union Special machines, operated by skilled craftspeople who understand the importance of proper tension and stitch quality.

Key construction details include chain-stitched waistbands, lock-stitched yoke seams, and bartacked stress points that prevent common failure areas.

The jeans are finished with copper hardware, leather patches, and signature touches like the 'shockoe' pocket bag interior.

Every pair undergoes quality inspection before being shipped, ensuring it meets the brand's exacting standards.

Red Rooster Coffee

"Organic, fair-trade specialty coffee roasted in small batches in the Blue Ridge Mountains."

A Living Tradition

Red Rooster Coffee is a specialty coffee roaster based in Floyd, Virginia, a rural town in the Blue Ridge Mountains known for its rich musical heritage and counter-cultural history.

Founded in 2010 by Haden Polseno-Hensley and Rose McCutchan, the company began as a modest operation to supply their local coffee house but has evolved into one of the premier roasters on the East Coast.

Red Rooster distinguishes itself through a dual commitment to high-quality coffee and deep social responsibility.

They are dedicated to sourcing organic and fair-trade beans, ensuring equitable compensation for farmers in origins like Ethiopia, Colombia, and Peru.

Domestically, they are a vital economic engine for their rural community, employing nearly 50 people and providing rare benefits for the service industry, such as comprehensive health insurance and on-site childcare.

This holistic approach to sustainability makes their coffee a 'conscientious' gift that supports both global agriculture and local community building.

Innovation Meets Craftsmanship

The coffee roasting process at Red Rooster combines sensory art with scientific precision.

It begins with carefully selecting single-origin and blended beans that meet their strict quality and ethical sourcing standards.

The roasting takes place in their Blue Ridge facility using Loring roasters, advanced machines that minimize environmental impact while maximizing flavor clarity.

Each batch is roasted to specific profiles developed through extensive cupping and testing, bringing out the unique characteristics of each bean's origin.

The roasting process involves carefully controlling temperature and airflow to develop the right balance of acidity, body, and aroma.

Once roasted, the coffee is quickly packaged in valve-sealed bags that allow gases to escape while preventing oxygen from entering, preserving freshness.

Quality control includes regular cupping sessions where the team evaluates flavor, aroma, and consistency.

Their coffees consistently score highly on Coffee Review and have won multiple Good Food Awards, testament to their commitment to excellence.

Emerson Creek Pottery

"Hand-painted, non-toxic stoneware pottery featuring botanical and nature-inspired designs."

The Founder's Vision

Emerson Creek Pottery is a heritage American ceramics studio located in the foothills of the Blue Ridge Mountains in Bedford, Virginia.

Originally founded in 1977 in Uxbridge, Massachusetts, the founders relocated the entire operation—including the kiln—to Virginia to access the region's natural clay resources and serene environment.

For nearly 50 years, the pottery has adhered to traditional manufacturing methods that prioritize safety and artistry.

A critical differentiator for Emerson Creek is their proprietary clay body, which is mixed in-house using raw materials sourced exclusively from North American mines.

This control over the supply chain ensures that all their pottery is certified lead-free and cadmium-free, a significant selling point for health-conscious consumers wary of imported ceramics.

The production involves forming pieces using either a RAM press or slip casting techniques, followed by hand-finishing to smooth edges.

The defining feature of their work is the hand-painting process; skilled artisans apply signature botanical designs, such as 'Summer Peaks,' 'Red Poppy,' and 'Blue Iris,' directly onto the raw glaze before firing.

The Art of Handcrafted Excellence

The pottery-making process at Emerson Creek begins with mixing their proprietary clay body from raw materials sourced from North American mines.

This clay is carefully formulated to be strong, non-toxic, and ideal for both functional and decorative ware.

Forming techniques include RAM pressing, where clay is pressed into plaster molds to create consistent shapes, and slip casting, where liquid clay is poured into molds for more complex forms.

After forming, pieces are carefully hand-finished to smooth any seams or rough spots.

The most distinctive aspect of Emerson Creek's process is the hand-painting of designs.

Skilled artists use Underglazes to apply botanical and nature-inspired motifs directly onto the bisque-fired pieces.

Each design is hand-brushed, ensuring that no two pieces are exactly alike.

After painting, pieces receive a clear glaze that enhances the colors and provides a smooth, durable surface.

The final firing reaches over 2,000 degrees Fahrenheit, transforming the clay into durable stoneware that's microwave, oven, and dishwasher safe.

Each piece is inspected for quality before being carefully packaged.

Patagonia

"Environmental and outdoor gear company with repair and manufacturing operations."

The Story Behind the Brand

Patagonia's Richmond facility represents the company's commitment to American manufacturing and environmental responsibility.

Located in Virginia's capital, this facility serves as a key hub for repairing and refurbishing the company's products, embodying their 'Don't Buy This Jacket' philosophy that encourages repair over replacement.

The Richmond operation works closely with the company's global supply chain to ensure that products bearing the Patagonia name meet the highest standards for environmental and social responsibility.

The facility has become a model for how large outdoor companies can maintain domestic operations while serving national markets.

Employees at the Richmond facility are involved in various aspects of product lifecycle management, from repair to refurbishment to resale, all guided by Patagonia's mission to build the best product, cause no unnecessary harm, and use business to inspire and implement solutions to the environmental crisis.

A Commitment to Quality

The Richmond facility's operations center on extending the life of Patagonia products through repair, refurbishment, and resale programs.

The repair process begins with careful assessment of returned or damaged garments and gear.

Skilled technicians use specialized techniques to restore products to like-new condition, including replacing zippers, repairing tears, and re-waterproofing outerwear.

The refurbishment process involves thorough cleaning, minor repairs, and quality inspection before items enter the 'Worn Wear' program for resale.

The facility also serves as a demonstration center for Patagonia's repair workshops, teaching customers how to repair their own gear and extending product lifecycles.

Quality control is paramount, with each repaired item meeting the same standards as new products.

The entire operation runs on renewable energy and follows circular economy principles, keeping products in use longer and reducing environmental impact.

Bee's Keep

"Handcrafted wooden beekeeping supplies and hive components."

A Living Tradition

Bee's Keep represents the intersection of traditional craftsmanship and sustainable agriculture.

Based in Charlottesville, Virginia, this artisan workshop specializes in creating high-quality beekeeping equipment using traditional woodworking techniques.

The company was founded by beekeepers who understood that the health of honeybee colonies depends not only on good practices but also on the quality of the equipment used to house and manage them.

Every piece is crafted with care, using sustainably sourced hardwoods that can withstand years of exposure to the elements while providing a healthy environment for bee colonies.

The workshop has become a gathering place for the local beekeeping community, offering classes, workshops, and demonstrations that teach sustainable beekeeping practices.

Bee's Keep products are sought after by both commercial beekeepers and hobbyists who value American craftsmanship and want to support pollinators through quality equipment.

Time-Honored Techniques

The woodworking process at Bee's Keep begins with selecting sustainably sourced hardwoods, including cedar and pine, known for their natural resistance to weather and insects.

Each piece of lumber is inspected for quality and defects before being milled to precise dimensions using traditional and modern woodworking tools.

Joinery is critical in beekeeping equipment, where joints must be tight and durable to prevent drafts and leaks that could harm bee colonies.

Traditional techniques like dovetail and mortise-and-tenon joints are used where appropriate, reinforced with food-safe adhesives.

The assembly process involves careful attention to detail, ensuring that boxes fit together perfectly and frames hang straight.

Each piece is sanded smooth and finished with natural oils that are safe for bees while protecting the wood from weather.

Final inspection includes checking for proper dimensions, smooth surfaces, and secure construction that will last for decades of use.