Pacific Northwest Innovation

"From Seattle's glass studios to Prosser's cherry orchards—discover five brands where sustainability meets craftsmanship in the Evergreen State."

Where Innovation Meets Sustainability

Washington State's consumer manufacturing sector represents a sophisticated fusion of innovation, environmental stewardship, and artisanal craft. The Pacific Northwest's distinct cultural ethos values sustainability, authenticity, and the 'maker' movement. From the orchards of the Yakima Valley to the industrial districts of Seattle, Washington brands leverage local materials and a highly skilled workforce to produce premium goods that compete on quality and narrative rather than price. These five stories represent the best of Washington's manufacturing heritage—brands that have found success by prioritizing ethical production, vertical integration, and a commitment to their local communities.

Liberty Bottleworks

"The only manufacturer producing metal water bottles entirely within the United States."

The Story Behind the Brand

Liberty Bottleworks stands as a singular entity in the hydration market, distinguished as the only manufacturer producing metal water bottles entirely within the United States.

In a sector almost exclusively dominated by stainless steel imports from East Asia, Liberty Bottleworks has carved out a defensible niche by prioritizing environmental sustainability, circular economy principles, and advanced digital customization.

Founded in 2010 by Tim Andis and Ryan Clark in the Yakima Valley, the company was established with the explicit goal of repatriating manufacturing jobs.

The company's early years were marked by rapid growth and high visibility, including features in national 'Made in America' showcases.

In 2018, the company was acquired by Olympia Tools, but the critical outcome was the retention of the manufacturing facility in Union Gap, preserving the local jobs that were central to the brand's founding mission.

How It's Made

Liberty Bottleworks' production process is a case study in sustainable industrial engineering.

Unlike competitors using virgin stainless steel, Liberty utilizes recycled aluminum—a material that is infinitely recyclable and requires significantly less energy to reprocess.

The manufacturing line employs deep-draw technology, utilizing a body-maker machine similar to those used in military munitions casings, resulting in bottles that are exceptionally durable and lightweight.

The factory employs a vacuum system to collect all scrap metal shavings, which are then recycled.

Furthermore, water used in production is filtered and reused up to four times.

The exterior uses INX CP100 cylindrical digital printers enabling high-resolution (1,000 dpi), full-color imagery with tactile texture capabilities—a bottle featuring a baseball can have raised 'laces' the user can feel.

Fran's Chocolates

"Luxury chocolates famous for pioneering the salted caramel trend in the US."

The Founder's Vision

Fran's Chocolates is widely acknowledged as one of the pioneers of the artisan chocolate movement in the United States.

Established in 1982, the company predates the modern 'craft chocolate' boom by decades.

Founder Fran Bigelow was inspired by a transformative trip to Paris to bring the refined, less-sugary aesthetic of French chocolate-making to Seattle.

Starting with a small patisserie in Madison Valley, Bigelow's commitment to 'pure flavors' and elegant presentation built a cult following.

The business has successfully transitioned into a second-generation family enterprise—Fran's daughter, Andrina Bigelow, serves as CEO, while her son, Dylan Bigelow, serves as Director of Chocolate.

The brand achieved national and international fame when the Smoked Salt Caramels became known as a favorite indulgence of President Barack Obama.

A Commitment to Quality

Production takes place in a restored historic building in Seattle's Georgetown neighborhood.

Unlike 'bean-to-bar' makers who process raw cacao beans, Fran's operates as a chocolatier, sourcing high-quality chocolate couverture primarily from Valrhona in France—ensuring a consistent flavor profile that serves as a reliable canvas for their fillings.

The dairy components—cream and butter—are sourced locally from Fresh Breeze Organic Dairy in Lynden, Washington.

The production of their flagship Salted Caramels is a precise operation: butter and sugar are slow-cooked in copper kettles to achieve a specific texture—soft, yet structured enough to hold its shape when dipped.

The 'Gray Salt Caramels' are coated in dark chocolate and finished with sea salt from Brittany, France.

The 'Smoked Salt Caramels' are coated in milk chocolate and topped with salt smoked over Welsh oak.

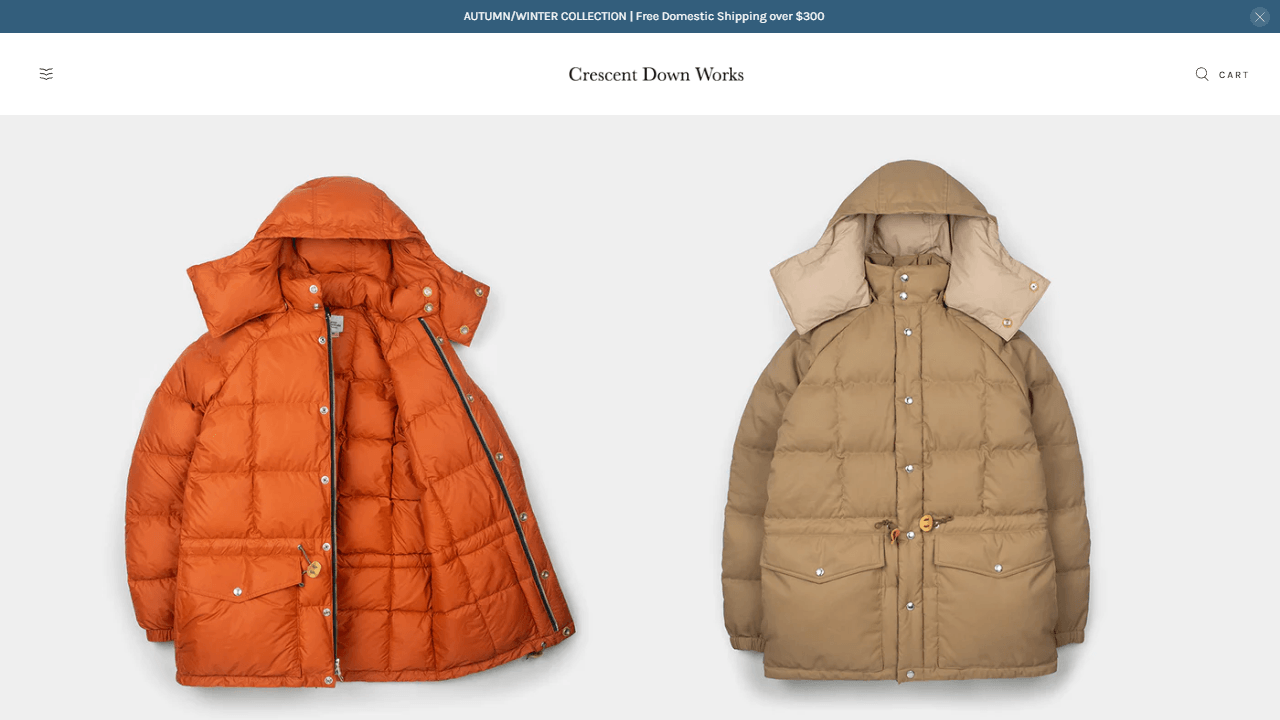

Crescent Down Works

"Heirloom-quality down vests and parkas handmade in Seattle since 1974."

A Living Tradition

Crescent Down Works represents the resilience of the textile industry in the United States.

In an era where apparel manufacturing has almost entirely shifted to Asia, Crescent Down Works maintains a vertically integrated factory in Seattle.

Founded in 1974 by Anne Michelson, a former employee of the legendary Eddie Bauer (who patented the first down jacket), the company was born from a passion for the outdoors and a desire for superior gear.

The company remains family-run, preserving a direct link to the golden age of American outdoor gear manufacturing.

The brand is positioned in the 'heritage workwear' and 'gorpcore' markets, appealing to consumers who value durability, timeless design, and ethical production over fast fashion trends.

Their products have found significant success in the Japanese market, where there is a strong appreciation for 'Americana' and heritage brands.

The Art of Handcrafted Excellence

The core differentiator for Crescent Down Works is its 'made-to-order' production model.

Rather than producing massive inventories based on speculative demand, the company produces garments in response to specific orders, reducing waste and ensuring high sell-through rates.

The factory, located in Seattle's SoDo industrial district, employs a team of long-tenured sewers and cutters—some with over 30 years of experience.

This retention of skilled labor is critical for working with down insulation, which is notoriously difficult to handle.

The insulation is 100% high-grade white goose down, ethically harvested, offering a superior warmth-to-weight ratio compared to duck down or synthetics.

The fabrics, often 60/40 cotton/nylon blends or ripstop nylon, are chosen for their durability and vintage aesthetic.

Chukar Cherries

"No-sugar-added dried cherries and chocolate-covered fruit from the Yakima Valley."

The Story Behind the Brand

Chukar Cherries exemplifies the 'value-added agriculture' model.

Located in Prosser, the epicenter of Washington's cherry and wine country, the company transforms a perishable commodity into shelf-stable, high-value gourmet products.

Founded in 1988 by Pam Montgomery after purchasing a 100-acre cherry orchard, the business was driven by agricultural necessity.

Montgomery observed that thousands of pounds of fruit were left unpicked after the commercial harvest.

She discovered that cherries left to dry naturally on the branch in the arid Eastern Washington sun developed a concentrated, intense flavor.

This led to the development of a proprietary drying process that replicates this natural dehydration.

Today, Chukar has successfully positioned itself as the quintessential 'Taste of the Northwest' gift, with a flagship store in Seattle's Pike Place Market.

How It's Made

Chukar Cherries operates a fully vertically integrated facility.

The company sources fresh cherries—primarily Bing, Rainier, and Montmorency Tart varieties—directly from local growers in the Yakima Valley.

Upon arrival at the Prosser facility, the fruit is washed, sorted, and pitted.

The drying process is the company's core competency.

Using warm air tunnels, the cherries are slowly dehydrated without the use of preservatives, sulfites, or added sugar.

This preserves the nutritional profile and natural taste of the fruit.

For their confectionery line, these dried cherries are then panned in chocolate using copper kettles.

The chocolate used is a European-style pastry blend, designed to complement rather than overpower the fruit.

The entire process, from receiving fresh fruit to packaging, is managed in-house.

Glassybaby

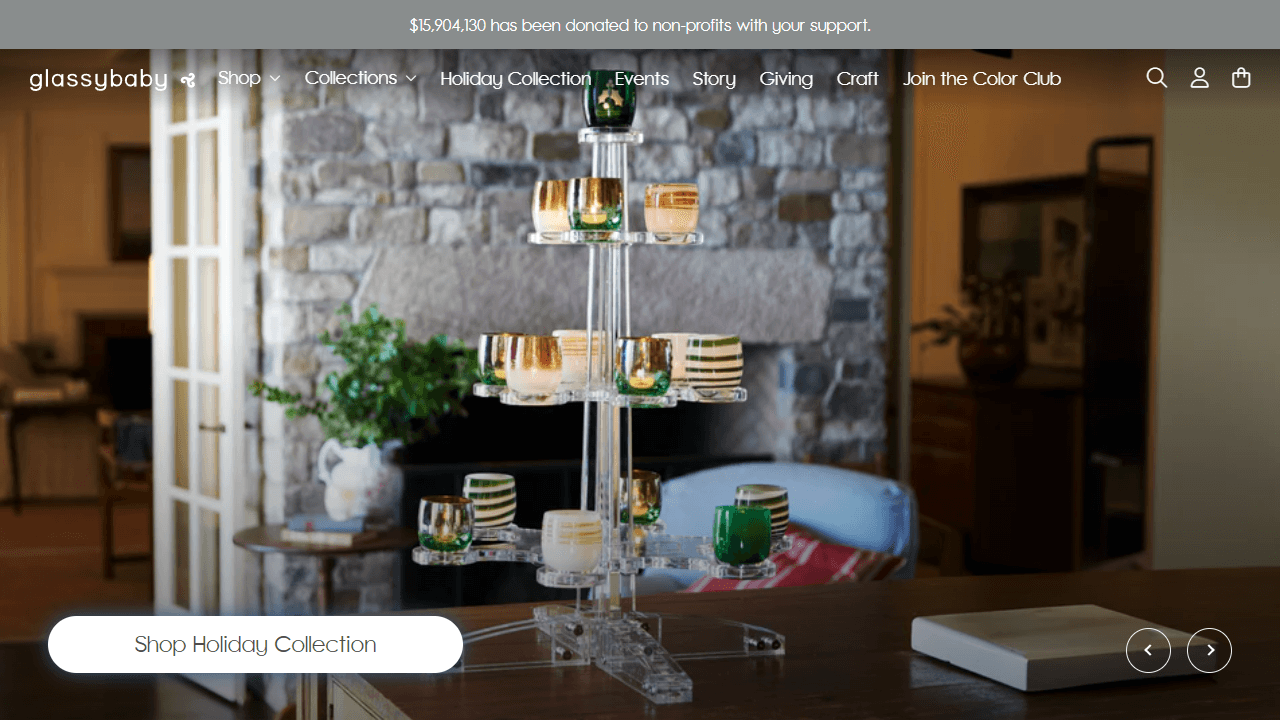

"Hand-blown glass votives with a mission of charitable giving—over $14 million donated."

Where Fire Meets Imagination

Glassybaby produces simple, hand-blown glass votive candle holders, but the product is secondary to the mission.

The brand operates on a 'philanthro-capitalist' model, where charitable giving is built into the cost structure.

Founded in 2001 by Lee Rhodes, a three-time cancer survivor, the concept was born from personal trauma and recovery.

Rhodes found that the light of a tea candle floating in a handmade glass cup provided her with a sense of peace during chemotherapy.

She began commissioning local glassblowers to make them, eventually turning a garage operation into a multi-million dollar business.

The core mission was established early: to donate a portion of revenue to charities helping cancer patients with unreimbursed costs.

To date, the company has donated over $14 million to causes supporting healing.

The Art of Handcrafted Excellence

Despite its growth, Glassybaby maintains a strictly manual manufacturing process.

The company employs teams of glassblowers in its Seattle hot shop.

The process involves three layers of glass to create the signature depth and glow—a gather of clear glass, followed by a layer of colored glass, and often another layer of clear.

The pieces are blown, shaped, and hand-trimmed.

This process requires significant skill and labor, justifying the price point.

The 'one-of-a-kind' nature of hand-blown glass means that each piece has unique variations, which the brand markets as a feature rather than a flaw.

Each hue is given a meaningful name—like 'Hope,' 'Joy,' or 'Kindness'—allowing the giver to tailor the message to the recipient.