America's Dairyland, America's Craft

"From Milwaukee's breweries to Sheboygan's boats—discover the brands keeping Wisconsin's manufacturing heritage alive."

Where Tradition Meets Innovation

Wisconsin has always been America's workshop, a state where craftsmanship runs as deep as the Great Lakes. From the leather aprons of Milwaukee's motorcycle builders to the precision engineering of Kohler's plumbing fixtures, Wisconsin makes things that last. This is cheese curds and manufacturing, where family farms supply artisan cheesemakers and industrial giants alike. Each brand in this collection represents a different aspect of Wisconsin's industrial heritage—motorcycles that defined American freedom, beer brewed with generations of expertise, boats that navigate the world's roughest waters. What ties them together isn't just geography; it's an uncompromising commitment to quality. In Wisconsin, they don't just make products—they craft legacies, passing down skills from master to apprentice, generation to generation.

Harley-Davidson

"America's iconic motorcycle manufacturer defining freedom for over 120 years."

The Founder's Vision

William S.

Harley and the Davidson brothers built the first Harley-Davidson in a shed behind their father's house in Milwaukee in 1903.

What started as a dream to build a motorized bicycle became the world's most iconic motorcycle brand.

Through two world wars, the Great Depression, and countless market changes, Harley-Davidson has remained true to its Wisconsin roots.

The company's Milwaukee headquarters still builds motorcycles using techniques passed down through generations of craftspeople.

Every bike tells a story of American independence, rebellion, and the open road.

Today, Harleys are built in Wisconsin, Pennsylvania, and Brazil, but the soul remains Milwaukee.

The Art of Handcrafted Excellence

Building a Harley-Davidson is part engineering, part artistry.

The process begins at the Pilgrim Road plant, where engine cases are cast from molten iron in a foundry that operates around the clock.

These cases are machined to tolerances tighter than a human hair, ensuring perfect fit and performance.

The famous V-twin engines are assembled by hand, with each technician responsible for the entire engine from start to finish—a tradition that ensures quality and pride.

Frames are welded by master fabricators, then painted in a process that takes days to complete.

Finally, engines and frames come together in final assembly, where every bolt is torqued to specification by technicians who take personal responsibility for each motorcycle.

Kohler

"Luxury plumbing fixtures and furniture with 150 years of craftsmanship."

The Founder's Vision

John Michael Kohler started Kohler in 1873 as a cast-iron foundry in the village that still bears his name.

In 1883, he had an idea that would change the industry: why not enamel these cast-iron sinks? That single innovation transformed a utilitarian object into a beautiful centerpiece.

Today, Kohler is a global powerhouse, but their commitment to American craftsmanship remains unchanged.

The company's Wisconsin campus includes foundries, assembly plants, and design centers where the world's finest plumbing fixtures are born.

From ornate Victorian designs to minimalist modern masterpieces, Kohler has been setting the standard for bathroom design for over 140 years.

How It's Made

Creating a Kohler fixture begins with molten iron poured into molds that create the basic shape.

These castings are then machined to precise specifications, ensuring perfect fit for all components.

The magic happens in the enameling process, where each piece is coated with a proprietary glaze that's fired at 1,500°F, creating a surface that's beautiful, durable, and easy to clean.

Kohler's engineers have developed over 300 enamel colors, from crisp whites to deep jewel tones.

Every fixture undergoes rigorous testing—thousands of flushes, hundreds of temperature cycles, and endurance tests that simulate decades of use.

Only when a fixture passes these tests does it earn the Kohler name.

S.C. Johnson

"Family-owned cleaning and household products company for over 135 years."

Innovation Born from Necessity

Samuel Curtis Johnson Sr.

founded S.C.

Johnson in 1886, creating a company that would become synonymous with American households.

From their headquarters in Racine, the Johnson family has guided the company for five generations, building brands that have become part of American life: Windex, Pledge, Shout, Ziploc, and the iconic Glade air fresheners.

What sets S.C.

Johnson apart is their long-term thinking—they've been investing in research, sustainability, and employee relations for over a century.

The company's 'Windex' was one of the first glass cleaners, and their innovations in aerosol technology revolutionized household cleaning.

Today, S.C.

Johnson operates in dozens of countries, but their Wisconsin roots remain strong.

Innovation Meets Craftsmanship

S.C.

Johnson's manufacturing process emphasizes both quality and sustainability.

Their Racine facility is one of the most advanced consumer products plants in the world, using biotechnology to develop new cleaning formulas and sustainable packaging solutions.

The company's scientists work in state-of-the-art labs, formulating products that clean effectively while being safe for families and the environment.

Manufacturing lines are designed for flexibility, allowing rapid changeovers between different products.

S.C.

Johnson has pioneered several packaging innovations, from trigger sprayers that provide precise application to the now-ubiquitous Ziploc bag.

Every product is tested extensively to ensure it meets the company's high standards.

Lands' End

"Classic American clothing brand known for quality and customer satisfaction."

The Founder's Vision

Gary Comer started Lands' End in 1963 as a mail-order sailing canvas company in Chicago.

Within a decade, he'd moved to Wisconsin and transformed the business into a renowned catalog retailer known for classic American style.

Lands' built its reputation on quality clothing, unconditional guarantees, and genuine customer service.

The company's Dodgeville headquarters has been the epicenter of American casual wear for over 50 years, where they've perfected the art of the button-down shirt, the canvas chino, and the perfect pair of jeans.

Their famous catalog arrived in millions of American homes, making Lands' End part of the family.

Today, they continue to innovate while staying true to their Midwestern values.

A Commitment to Quality

Lands' End products are designed to last, starting with careful selection of materials.

Their fabrics are sourced from trusted American mills and tested for durability, colorfastness, and comfort.

Design happens in Wisconsin, where teams create classic styles that won't go out of fashion.

The construction standards are exacting: bar-tacked stress points, real horn buttons, and premium trims that can withstand years of wear.

Every garment undergoes multiple fit sessions to ensure it looks good on real bodies.

Lands' End maintains detailed specifications for every style, ensuring consistency across all production runs.

Quality control happens at every step, from fabric inspection to final garment review.

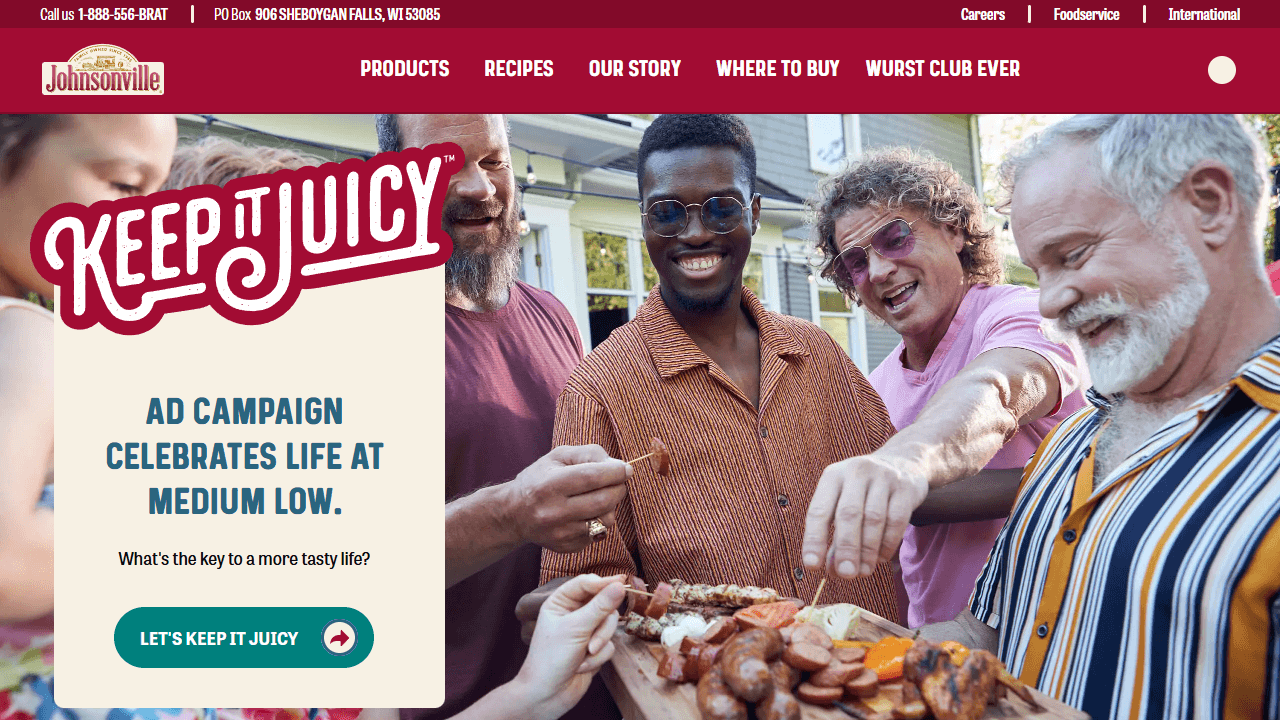

Johnsonville

"Premium sausage makers with authentic Wisconsin flavor since 1945."

The Founder's Vision

Ralph Johnson started Johnsonville in 1945, selling his wife's homemade bratwurst recipe from a small meat market.

Word spread quickly about the superior taste, and soon Johnsonville grew from a local butcher shop into America's premier sausage brand.

The company has always stayed true to Wisconsin traditions, using recipes passed down through generations and sourcing ingredients from local farms.

What makes Johnsonville special is their commitment to authenticity—they're still based in Sheboygan, still family-owned, and still making sausage the way Wisconsin families have for centuries.

Their brats are served at stadiums, cookouts, and dinner tables across America, but every one carries the spirit of Wisconsin.

Time-Honored Techniques

Johnsonville starts with the finest ingredients: premium cuts of pork from family farms, traditional spices imported from Europe, and natural hog casings that give their sausages that perfect snap.

The pork is ground fresh daily, then mixed with Johnsonville's proprietary spice blends—formulas developed decades ago and refined over generations.

Stuffing happens quickly, using natural casings that allow the sausage to expand as it cooks.

Every batch is tested for quality, from texture to flavor.

Johnsonville smokes their summer sausage in hickory wood smokehouses, a process that takes 12 hours and develops the deep, rich flavor that makes their products special.

The result is sausage that tastes homemade because, in many ways, it still is.

Marinette Marine

"Naval shipbuilding yard constructing America's next-generation warships."

The Story Behind the Brand

In the shipyards of Marinette, Wisconsin, the Navy's future is being built one steel plate at a time.

Marinette Marine has been constructing vessels for the U.S.

Navy and Coast Guard since 1942, when the company built the first LST (Landing Ship, Tank) for World War II.

Today, they're the builder of the Freedom-class Littoral Combat Ship, fast and agile warships designed for operations in shallow coastal waters.

Every inch of these vessels is built with American steel, American craftsmanship, and American pride.

The shipyard employs hundreds of skilled tradespeople—welders, electricians, pipefitters—who take personal responsibility for building the ships that protect America's interests around the globe.

How It's Made

Building a Navy warship is a three-year process that begins with cutting steel plates on computer-controlled cutting systems.

These plates are formed into the ship's hull using techniques passed down through generations of shipbuilders.

Welding is critical—every seam must be perfect, inspected multiple times before moving forward.

The ship takes shape in a massive building hall, where hundreds of workers install systems, equipment, and weapons.

Marinette Marine has pioneered modular construction, building large sections of the ship separately, then moving them into position with enormous cranes.

Each ship undergoes sea trials, where every system is tested at full power before delivery to the Navy.